St. Paul, MN (August 16, 2019) — According to Moldmaking Technology Magazine, the Moldmaking Index increased slightly over the prior month led by production and employment. Although only two of the Index’s six components supported the Index’s move higher, only exports reported contracting activity.

St. Paul, MN (August 16, 2019) — According to Moldmaking Technology Magazine, the Moldmaking Index increased slightly over the prior month led by production and employment. Although only two of the Index’s six components supported the Index’s move higher, only exports reported contracting activity.

The Gardner Business Index (GBI): Moldmaking edged slightly higher in June to 52.3, signaling some increase in business activity compared to the prior month. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50, the greater the change in business activity. Compared to June 2018, the Index is 11.4% lower.

The May 2018 reading marks the end of a string of substantially elevated readings caused by the market cycle’s peak in the first half of 2018. Gardner Intelligence’s review of the month’s underlying data found that production and a significant turnaround in employment lifted the Index higher. New orders, supplier deliveries and backlogs all expanded slightly, but fell below the average component reading, pushing the Index lower. For the month, only exports experienced a contraction.

Employment activity has increased sharply since its nadir in late 2018. The latest monthly reading of employment activity nearly matched the record high set at the peak of the most recent business cycle.

Including June’s results, the 3-month moving average reading for new orders and production continues to expand. The expansion in new orders remains hampered by weakness in exports. Exports have been contracting modestly since the middle of 2018, the timing coincides with the start of tougher U.S. trade regulations with certain trading partners.

Employment data provided by survey participants to the Moldmaking Index continue to report strong growth after setting a recent low at the end of 2018. June’s employment reading was the highest since March 2018, placing this month’s employment activity change on par with the level of activity recorded at the peak of the latest business cycle.

Read more from Michael Guckes, Chief Economist/Director of Analytics, Gardner Intelligence at: https://www.moldmakingtechnology.com/blog/post/moldmaking-index-edges-higher-on-production-and-employment

One of the first manufacturers in the United States to invest in a hybrid additive manufacturing machine to reduce cycle time and cost for complex parts is thriving in this economy.

Custom Mold & Design remains at the forefront of new and innovative part and process developments over the past 50 years to ensure it provides its clients with a competitive advantage. As the go-to mold manufacturer for the medical device, electronics, defense and industrial markets, Custom Mold & Design prides itself on adopting technology early on while everyone else catches up. “We want to be on the leading edge of technology,” Vice President Lester Jones says. “It’s a challenge exploring uncharted territory, but a positive one.”

Based in Forest Lake, Minn., Custom Mold & Design specializes in mold making, engineering, design and development and assembly. As an outsourcing partner, the company can handle as much or as little of its clients’ projects as needed. Custom Mold & Design combines an experienced design and engineering team with highly advanced technology along with the best-in-class equipment in the industry. At every step, clients can expect careful consultation, attention to detail and customized services that meet their customers’ needs and produce quality results.

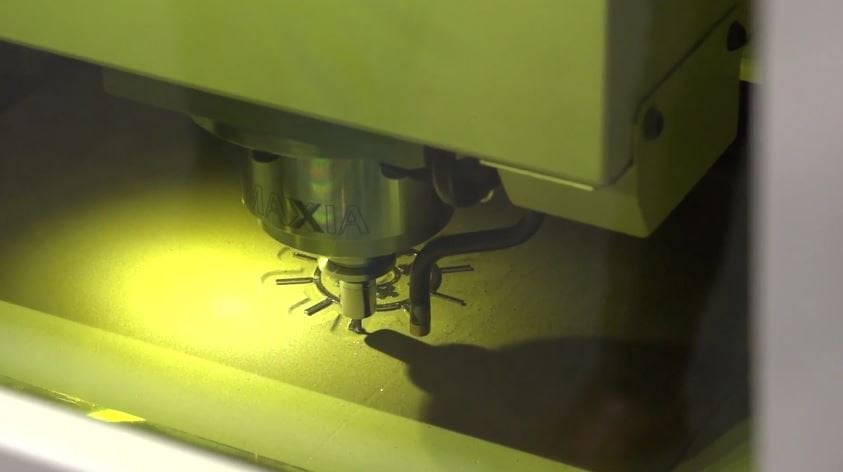

In October 2018, Custom Mold & Design invested in the Matsuura LUMEX Avance-25 Metal Laser Sintering Hybrid Milling Machine, a powder bed metal additive manufacturing platform with subtractive machining capability. The process produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. Often referred to as a “one machine, one process” system, the Matsuura LUMEX series allows for the production of the most complex and challenging parts through total manufacturing by digital engineering using 3-D data.

The Matsuura LUMEX Avance-25 is a game-changer for Custom Mold & Design. “Previously in the mold building industry, we learned how to use 3-axis CNC machining centers. Then came 5-axis machining and we took that on. With all of these technologies there is a learning curve, but you are essentially doing the same thing with new modifications,” Jones says. “The LUMEX Avance-25 involves working with powder and laser sintering, which is completely different. We have assigned our best people to learn this technology, essentially taking someone who is efficient at 3- and 5-axis machining and throwing them in the deep end of the pool to learn this technology. It certainly requires an investment and patience, but it is rewarding to participate in new and exciting technology and grow professionally. The LUMEX Avance-25 has provided opportunities, as well as challenges for our people.”

For more information on Custom Mold & Design, please visit: custommold.net

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information on Matsuura products, contact: [email protected] or visit: www.matsuurausa.com.