MX Series

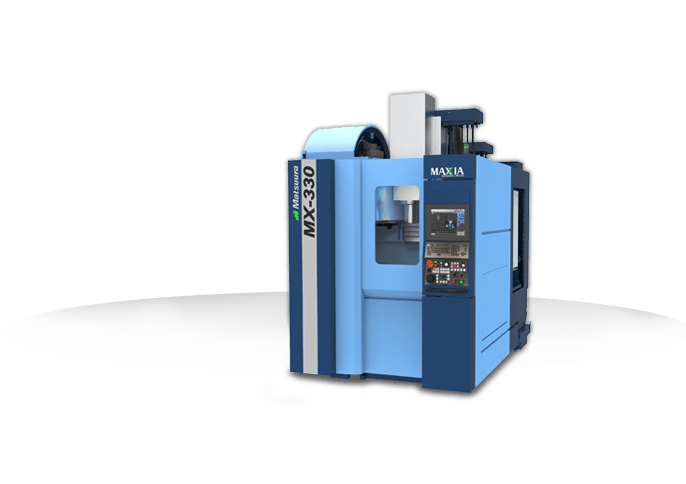

MX-330

5-Axis Vertical | Machining Center

The MX-330 is cost-effective and offers a large work envelope in a compact footprint. The MX-330’s exceptional ergonomics, intuitive controls, and full simultaneous 5-axis capability allow machine shops to meet their customers’ increasing demand for shorter lead-times and higher tolerances across multiple faces.

MX-330 PC10

5-Axis Vertical | Machining Center

The MX-330 PC10 features a compact floor plan with a large work envelope and high rigidity. Its pallets are compatible with the MAM72-35V and MX-420, making it easy to transfer work between platforms. Maximize manufacturing floor space, reduce training time, and improve productivity.

MX-420 PC10

5-Axis Vertical | Machining Center

The MX-420 PC10 is configured with 10 pallets and 90 different tools, making it a uniquely efficient machine with a minimal size. It also works in tandem with the MAM72-35V and MX-330, with easily transferable pallets that can be used across platforms.

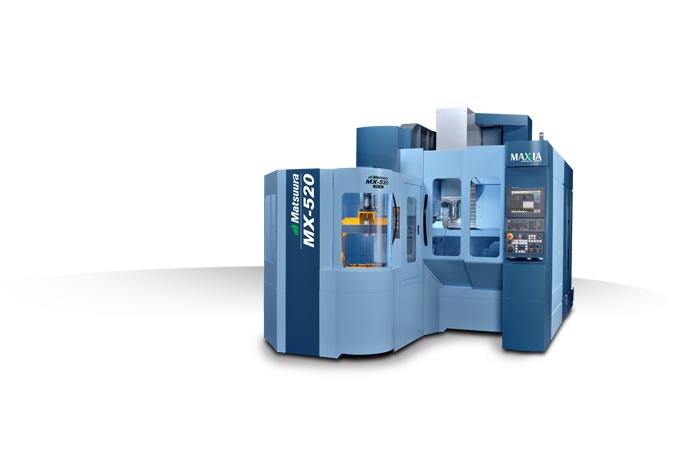

MX-520

5-Axis Vertical | Machining Center

The MX-520 is as efficient as it is adaptable, with customizable table and pallet options, high rigidity, and high precision. Tailored to fit numerous production needs, its automated operation and ergonomic design improve productivity on a variety of projects.

MX-520 PC4

5-Axis Vertical | Machining Center

The MX-520 PC4 features high rigidity and repeatability, and Matsuura’s extended unmanned operation. With a minimal footprint and the unique ability to swap pallets with MAM72-52V, it’s an ultra-efficient use of space.

MX-520T

5-Axis Vertical | Machining Center

This multi-tasking machining center combines 5-axis machining and turning processes, while retaining the user-friendliness of the MX series.

MX-850

5-Axis Vertical | Machining Center

The MX-850 offers customizable tables and pallets, high rigidity, and a large work envelope. With multiple table options and guaranteed accuracy, it’s a machine that can handle a variety of products with precision and speed.

MX-850 PC4

5-Axis Vertical | Machining Center

Compatible and compact, the MX-850 PC4 features a huge work envelope in a space-saving frame. High rigidity and repeatability ensure that production is carried out with precision and speed.

MAM72 Series

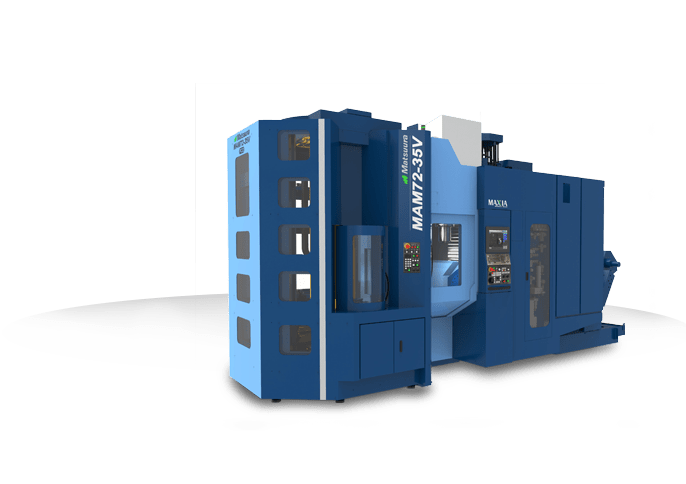

MAM72-35V

5-Axis Vertical | Machining Center

The MAM72-35V can withstand continuous production for up to 72 hours. It’s designed to handle a greater workpiece size than existing Matsuura models with its tailstock option and extra support for long workpieces and tall tombstone fixtures. MAM72-35V: 30+ years of Matsuura expertise distilled into one machine.

MAM72-42V

5-Axis Vertical | Machining Center

The efficient, powerful, and versatile MAM72-42V features a tailstock option and extra support for long workpieces and tall tombstone fixtures. Its pallet and tool options are compatible with the MAM72-35V, and, like other MAM series machines, it can support continuous production for up to 72 hours.

MAM72-52V

5-Axis Vertical | Machining Center

Specially designed for long operation with PC15 and 330 tool ATC standard, the MAM72-52V can support continuous production for up to 72 hours. This ability, combined with a compact size and large pallet changer, makes the MAM72-52V a highly efficient, accurate machine.

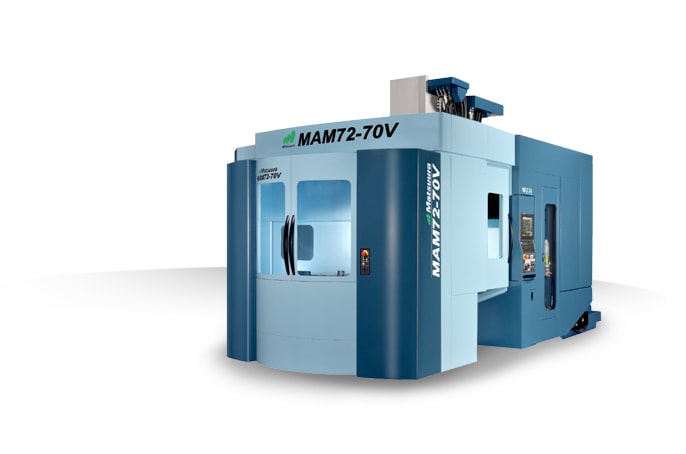

MAM72-70V

5-Axis Vertical | Machining Center

The MAM72-70V has the largest work envelope of any Matsuura 5-axis vertical machine. With numerous automation options and the ability to sustain continuous production for up to 72 hours, it can handle demanding production needs day and night.

MAM72-100H

5-Axis Horizontal | Machining Center

Designed with an extra-large work envelope, adaptable automation options, and the capability to support up to 72 hours of continuous production, the MAM72-100H is a powerful, precise, and efficient addition to your workspace.

CUBLEX Series

CUBLEX-35

5-AXIS MULTI-TASKING | Machining Center

The CUBLEX-35 is designed for maximum efficiency. With turning, grinding, and cutting all in a single machine, the CUBLEX-35 can produce complex parts faster and with incredible accuracy. A large pallet and tool changer allow for automated, 24/7 operation, so around-the-clock production is effortless.

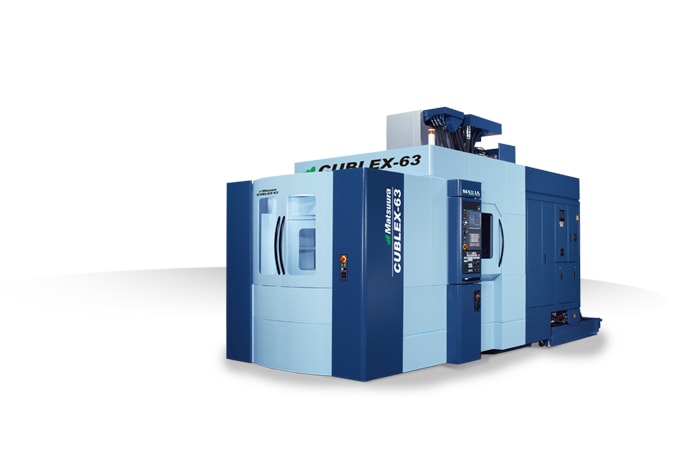

CUBLEX-63

5-Axis Multi-Tasking Machining Center

The CUBLEX-63 can handle turning, grinding, and cutting—all on one machine platform. With the CUBLEX-63, complex parts can be produced in fewer steps, reducing cycle times. A large pallet and multiple tool changers allow for 24/7, lights-out operation, ensuring maximum efficiency and easing the strain of labor shortages.

H.Plus Series

H.Plus-300

Horizontal | Machining Center

Get more done in one machine with the H.Plus-300. Compatible with FASTEMS systems and configured with the Matsuura-made direct drive 4-axis table, this powerfully efficient machine can shift and adapt to meet changing production needs.

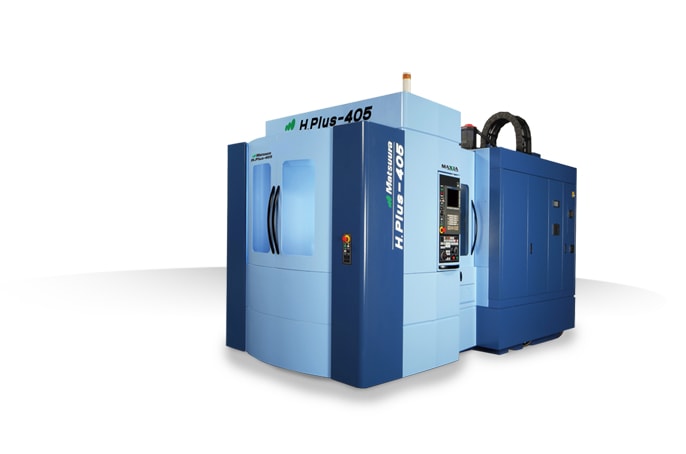

H.Plus-405

Horizontal | Machining Center

The H.Plus-405 features the Matsuura-made direct drive 4-axis table, Y-axis stroke extension, and compatibility with FASTEMS systems. Uniquely versatile, it delivers long periods of reliable operation, high accuracy, and efficient production.

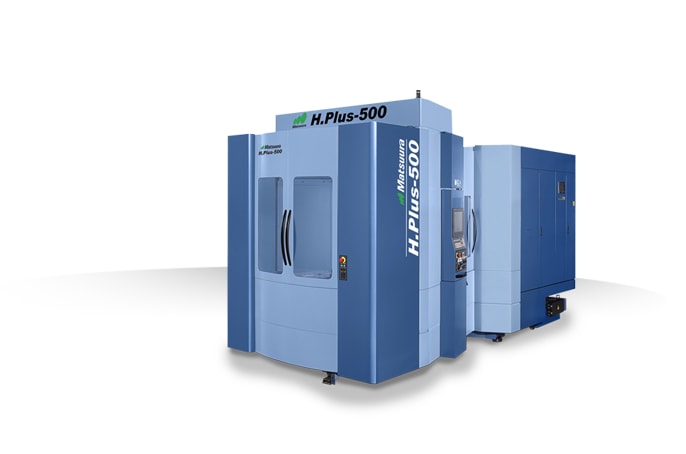

H.Plus-500

Horizontal | Machining Center

The H.Plus-500 is uniquely configured with the Matsuura-made direct drive 4-axis table and specially designed to be compatible with FASTEMS systems. Adaptable, reliable, and high-speed, the H.Plus-500 is a highly productive machine that can tackle any project.

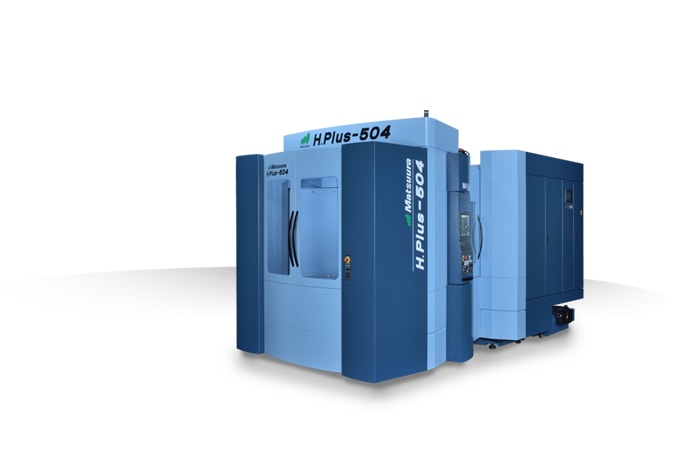

H.Plus-504

Horizontal | Machining Center

With expandable automation, compatibility with FASTEMS systems, and a large work capacity, the H.Plus-504 is the powerhouse of any project. No matter the ask, this machine’s high speed, high accuracy, and high rigidity offer reliable performance every time.

H.Plus-630

Horizontal | Machining Center

Adaptable and efficient, the H.Plus-630 is designed with the Matsuura-made direct drive 4-axis table and a substantial work envelope. It’s also compatible with FASTEMS systems and can handle around-the-clock machining.

VX Series

VX-660

3-Axis Vertical | Machining Center

The VX-660 offers state-of-the-art technology and high rigidity at an affordable price, making it a uniquely cost-effective manufacturing solution. Experience exceptional quality and unmatched performance for less.

VX-1000

3-AXIS VERTICAL | Machining Center

High-quality, low-cost production is a given with the VX-1000. Superior construction and premium components make it a reliable yet accessible machine for any shop floor. Throughout projects, it delivers high rigidity and accuracy, thanks to state-of-the-art technology.

VX-1500

Vertical | Machining Center

The VX-1500 makes high-quality, efficient production more affordable. With this machining center, high rigidity, precision, and Matsuura’s state-of-the-art technology are all packed into one compact, cost-effective design.

V.Plus Series

V.Plus-550

3-AXIS VERTICAL | Machining Center

Cost-effective, user-friendly, and exceptionally efficient. The V.Plus-550 incorporates decades of Matsuura machining expertise in its superior construction and premium components, ensuring reliable operation and profitability with every run.

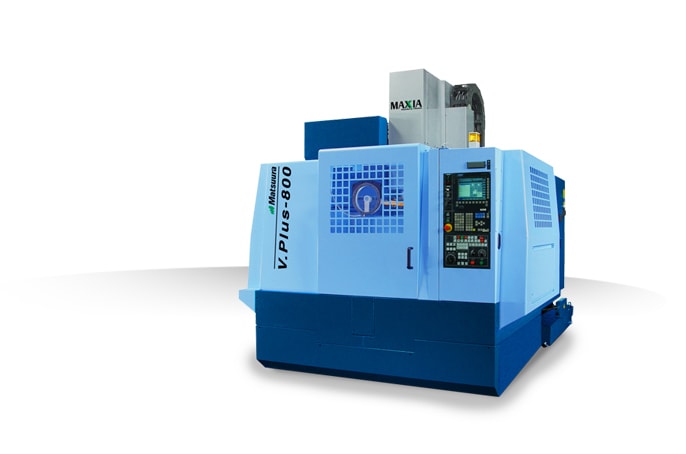

V.Plus-800

3-AXIS VERTICAL | Machining Center

The V.Plus-800 features superior construction and premium components, so high-quality, precise performance is assured. Powerful, yet user-friendly, it can tackle any production need in any environment.

Linear Motor Series

LF-160

5 AXIS VERTICAL | Machining Center

The LF-160 features the highest number of pallets in a 5-axis machine and an ultra-low vibration spindle, ensuring expert precision and exceptionally high accuracy with every run. It’s the ideal machine for small or delicate parts, such as medical devices and implants.

LV-500

3 AXIS VERTICAL | Machining Center

The LV-500 is the ultimate 3-axis vertical machine. Equipped with fast and accurate linear motors, it is designed for high-speed, high-precision machining. It also features an ultra-low vibration spindle, making it ideal for machining precision molds and optical components.

LX-160

5 AXIS VERTICAL | Machining Center

Ideal for high-tech, fast-paced industries such as aerospace and medical, the LX-160 features exceptionally fast cutting and micro tools up to 46,000 RPM. Its linear motors ensure speed and precision and its compact size boasts the highest number of pallets in a 5-axis machine.

LUMEX Series

METAL LASER SINTERING | Hybrid Manufacturing

The LUMEX Avance-25 metal laser sintering hybrid milling machine is a powder bed metal AM platform with subtractive machining capability. The machine combines selective laser sintering (SLS) along with high-speed milling (HSM) commonly called Hybrid AM.

Metal Laser Sintering | Hybrid Manufacturing

The LUMEX Avance-60 combines the flexibility of the 3D laser sintering 3D printing technique with the precision of conventional milling for the additive manufacturing of finished quality parts with maximum precision.