St. Paul, MN (May 21, 2020) — Matsuura’s LUMEX technology makes effective mold/gas venting possible and improves the quality of molds. Using porous structures in any place, the LUMEX Avance Series of machines lets the mold maker anticipate potential molding problems, such as gas burning and poor weld line formation, then address them thereby promoting quality improvements and reduced mold development cycles.

St. Paul, MN (May 21, 2020) — Matsuura’s LUMEX technology makes effective mold/gas venting possible and improves the quality of molds. Using porous structures in any place, the LUMEX Avance Series of machines lets the mold maker anticipate potential molding problems, such as gas burning and poor weld line formation, then address them thereby promoting quality improvements and reduced mold development cycles.

Matsuura’s LUMEX, a powder-bed additive machine with traditional subtractive capability designed specifically for injection mold tooling, facilitates the elimination of complications caused by gas traps in injection mold tools.

Matsuura LUMEX machines allow for air permeability to be controlled freely by creating a porous structure, simply by adjusting the density of the built part. This achieves gas venting more effectively than any other machine or technology. Users can expect reductions in fill time, fill pressure, prevention of uneven filling, and elimination of gas burning.

With Additive manufacturing (AM), customers realize geometric features no other process can produce. The laser sintering adds layers of material, and the Matsuura LUMEX milling spindle subsequently machines the material to ensure a quality surface finish. Producing mold cores and cavities in this way leverages additive’s capabilities to produce molds with conformal cooling channels, and to make sintering density changes in molding applications that require placement of porous structures to facilitate gas venting. In addition, laser sintering enables high aspect features to be produced by building them one layer at a time, eliminating the need to create them via traditional EDM.

Gas traps are a frequent drawback in injection molding, causing burning, pinholes and poor finished part quality. The gas traps are caused by gas pockets forming as the ‘melt fronts’ of the molten plastic, which is injected under pressure into injection mold tool cavities, come together before the gas has escaped naturally through the split lines of the tool; this traps the super-heated gas within the cavity burning the plastic.

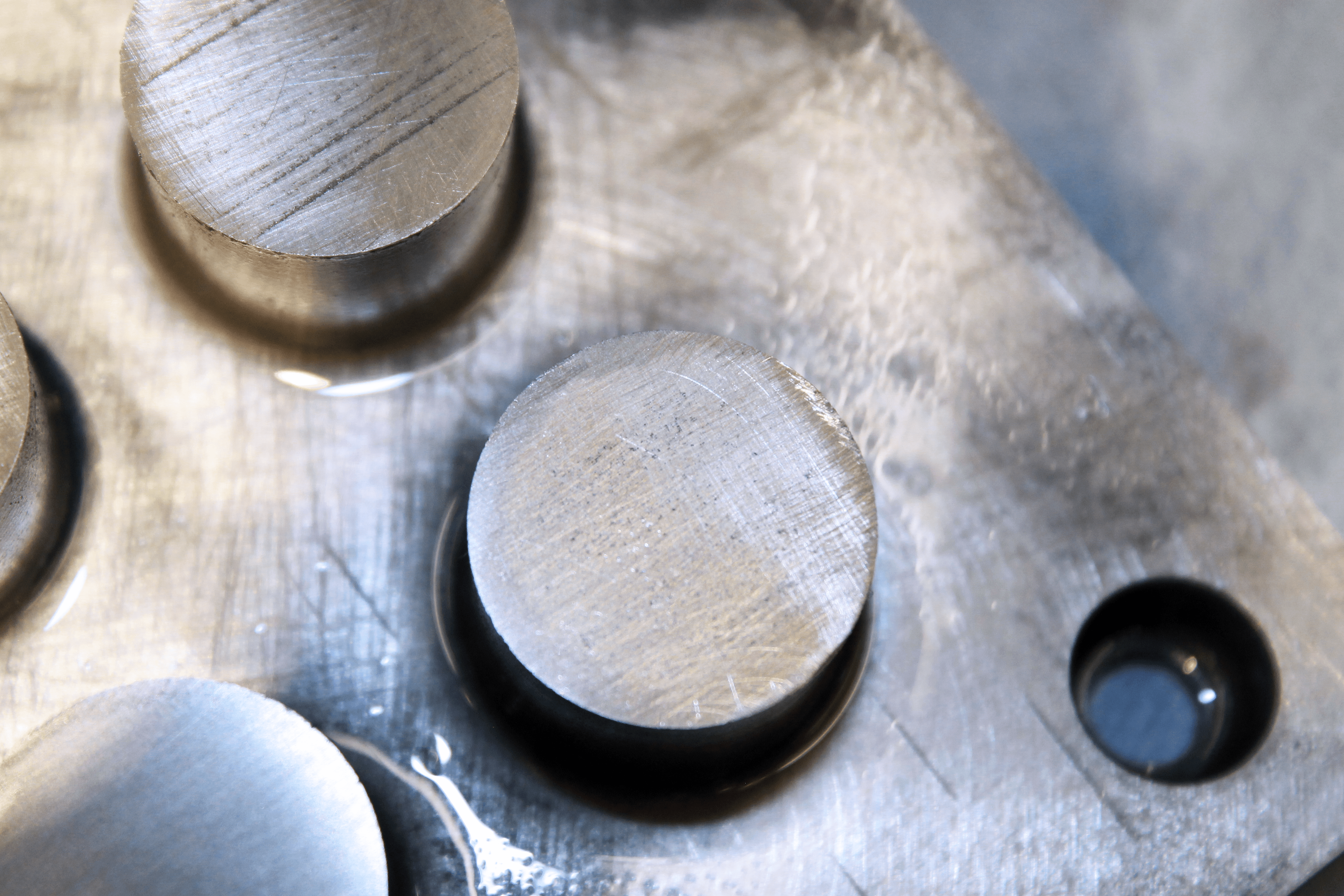

Utilizing the Matsuura LUMEX Technology, customers build inserts layer by layer, incorporating many micro-pores, each just a few microns in diameter, through which gas can escape, without adversely affecting the quality of the tooling surface.

The inserts are 3D laser sintered in steel or other metals, to match the exact requirements of each injection mold tool. The dimensions and characteristics of the gas escape channels are optimized to reduce cycle times and boost productivity, while maintaining high levels of part quality, even for extremely complex designs.

These porous inserts can be manufactured into any 3D shape, both quickly and efficiently, facilitating the reduction of lead-times and removing the challenges produced by gas traps. This maintains the mold part’s quality and productivity.

Hybrid Metal Additive Manufacturing and machining is an extremely effective method of creating conformal cooled injection mold tool inserts. Matsuura’s hybrid technology is a proven solution for moldmakers.

In most cases, the proper implementation of the hybrid technology in a mold component will eliminate the need for EDM. This in and of itself is a large time saver in the mold build process. Many components can be completely machined in the hybrid machine, there is an elimination of queue times to get other work completed on a component, typically reducing overall mold build time.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information on Matsuura LUMEX products, please contact: [email protected] or visit: www.matsuurausa.com.