Mitsubishi Chemical Advanced Materials Plastics

Mitsubishi Chemical Advanced Materials Plastics is a fully integrated manufacturer of injection-molded systems-critical polymer applications and sub-assemblies. It prides itself on delivering customized design, tooling, molding and assembly from a single source.

Challenges

- The extensive process to validate medical devices takes years to complete

- Lack of additive manufacturing technology to 3D print high-end engineering plastics

- Prototype mold construction and validation can be very time consuming and costly

Keys to Success

- Implement a process based on NX topology optimization for designers to achieve new, complex mold design

- Partner with Simcenter Engineering to validate new mold design

- Produce complex mold design with hybrid additive manufacturing technology based on 3D metal printing

Results

- Used new 3D printing techniques to reduce mold insert production lead time by up to 55 percent compared to conventional machining

- Realized 60 percent reduction in material weight compared to traditional subtractive design

- Reduced mold production time to one week (process normally takes eight to 16 weeks)

“Working with Matsuura Machinery, cards PLM Solutions and Siemens Digital Industries Software helped us prove that we can change the design of a mold and actually improve the product.”

Kristof Declerck, Project Development Engineer

MCAM

Medical device validation

In the medical device industry, validating a single new part can take up to three years. The extensive validation process often causes massive delays in products’ time-to-market, which can jeopardize a new product launch.

To address this issue, the industry is exploring additive manufacturing and high-end plastics to replace traditional manufacturing methods and materials. This approach allows companies to produce more parts at a faster pace and offers significant end-user benefits.

Plastics in medical devices

Compared to traditional materials such as metals, plastics are lighter and more affordable. Their material properties, which include flexibility, transparency and barrier properties, make them ideal for many medical uses, such as for bottles containing liquids and solvents. Plastics also take significantly less time to produce; using injection molding, companies can produce million of parts per year using multicavity tools. These tools are extremely cost effective, compared to other material and manufacturing techniques.

Finally, plastics offer much more design freedom than metals. Engineers are given extremely high levels of precision and reproducibility with plastics, which makes them ideal for an industry that relies on absolute precision.

Despite their advantages, for making prototypes for validation, the precision required by the medical device industry makes additive manufacturing of plastics a challenge for many companies. Due to technological shortcomings, traditional plastic additive manufacturing technology as of 2020 is unable to support mid- to high-end plastic printing such as polyamides, polyacetal plastics and polyether ether ketone (PEEK) at the required precision level.

A hybrid additive approach

The team at Mitsubishi Chemicals Advanced Materials Plastics (MCAM) was recently tasked with developing a new medical device for a client. Due to the limitations posed by current 3D plastic printing techniques, the team decided to 3D print a metal mold rather than print the plastic parts for the device itself.

Using this strategy, the MCAM team could balance the high precision required for the new part with the unique properties high end engineering plastic materials offer, while taking advantage of the speed of injection molding.

Once this course was agreed upon, the only remaining issues for the MCAM team were the lead time to manufacture a new mold and the number of iterations the mold would need before any validation or testing could be set up.

“The time it takes to develop a mold is dependent on the complexity of the part, but for the mold we wanted to create, production time could take anywhere from 8 to 16 weeks,” says Kristof Declerck, project development engineer, MCAM. “On top of that, we typically go through two-to-three iterations per mold, and each iteration takes two-to-four weeks in addition to the 8 to 16-week development time required. This creates too much delay in the design validation stage for our customer.”

Driven by its customer’s needs, MCAM needed a solution to reduce the time for the mold prototyping stage. The mold would come out too rough using traditional metal 3D printing solutions with no post-finishing techniques. Conventional post-finishing would be required, which would not sufficiently reduce the production time.

MCAM found a solution that addressed all the issues with traditional metal 3D printing in hybrid additive manufacturing. The team partnered with the Matsuura Machinery Corporation and invested in a LUMEX-Avance 25 hybrid metal 3D printing machine. This revolutionary new method of additive manufacturing combines 3D metal printing and finishing into one step, reducing the lead time to produce mold inserts by up to 55 percent compared to conventional machining.

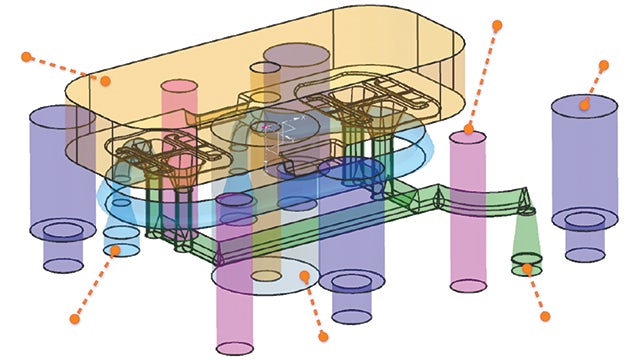

Overview of model construction and design space.

Overview of model construction and design space.

Smart design

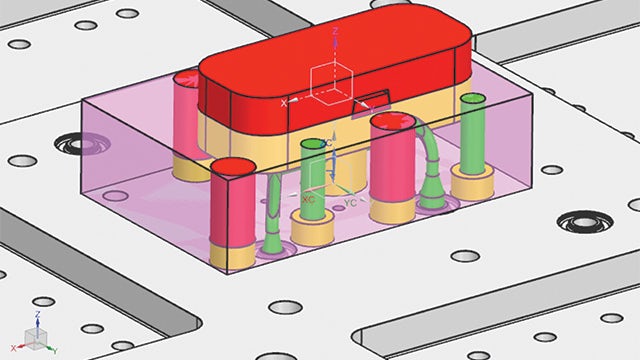

Now that MCAM found a printer to suit its needs, the next step was to reduce the build time. They realized the best way to achieve this would be to rethink the way they designed the mold inserts. The design added too much weight to the model, which increased the LUMEX-Avance 25’s build time. After experimenting with lattice-filled solids, MCAM discovered the benefits of topologic designs. This approach meant starting the design not from a block of material to be subtracted from, but from what the part required, such as load, pressure, cooling and fixations.

MCAM partnered with cards PLM Solutions to take advantage of the NX™ topology optimization for designers software. NX is a part of Siemens Xcelerator business platform of software, hardware and services. By defining boundaries, requirements and constraints on the plastic part’s 3D model, the team used the software to calculate the force lines and define where material would be required.

“Using this approach, we achieved a topologically optimized design,” says Declerck. “We were able to use only the exact amount of material that was absolutely necessary, which gave the strength needed for the application.”

Using the capabilities within NX topology optimization for designers, the MCAM team reduced material weight by 60 percent compared to traditional subtractive design. This material savings offered MCAM and its customer significant benefits by further reducing the lead time from design to real injection molded prototype parts.

Mold design boundaries to start the Topology calculation.

Mold design boundaries to start the Topology calculation.

Validating the topologic design with simulation

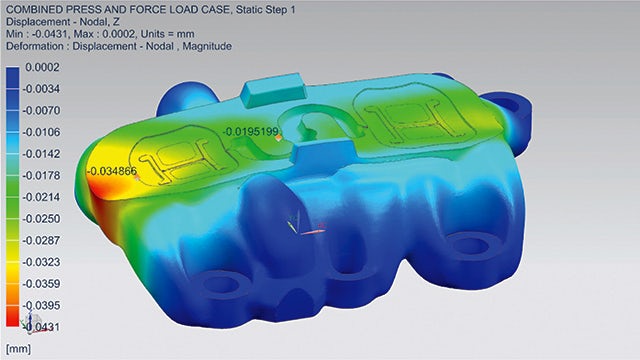

To ensure the new design met its requirements, MCAM contacted the Simcenter™ Engineering software team at Siemens. Many questions needed to be answered before the mold could go into production, including what would happen to the part under certain forces and pressures, whether it could hold such forces (such as internal stresses), and what type of deformation should be expected. If deformation was too high, cracking or openings could result and plastic could escape, which would ruin the entire part.

To validate the topologic design, a detailed finite element analysis (FEA) model was built in Simcenter 3D software and the linear analysis functionality of the Simcenter NASTRAN® solver was used to accurately calculate the structural performance. Using the Simcenter 3D postprocessing capabilities, the simulated stress and deformation responses were compared against their requirements and the design was signed-off for production.

“Our partnership with the Simcenter Engineering team gave us the confidence we needed to build a first prototype on the LUMEX-Avance 25,” says Declerck.

Using NX topology optimization for designers and validating the detailed design with Simcenter NASTRAN, MCAM greatly reduced the amount of material used and the weight of the mold by leaving out unnecessary sections. “The new, optimized design took only 10 hours to produce, a significant time savings compared to the 20 to 24 hours required with the subtractive design method,” says Declerck.

“Furthermore, the structural behavior observed on the manufactured prototype corresponded well with the structural response predicted by the FEA simulation model. This verification step was important to establish confidence in the virtual sign-off procedure.”

Detailed CAE performance evaluation.

Detailed CAE performance evaluation.

A new approach

Successfully completing this project gives the MCAM team confidence using this new approach. “We plan to use this approach in future projects using Siemens products for designing and validating complex mold systems,” says Declerck. “We are excited to work with the Simcenter Engineering team on future projects for validation.

“It was extremely critical to us at the start of this project that we gain the complete confidence in the design before it begins printing. When poor or incorrect designs are sent to the printer, it becomes very costly and time-consuming. Working with Matsuura Machinery, cards PLM Solutions and Siemens Digital Industries Software helped us prove that we can change the design of a mold and actually improve the product.”

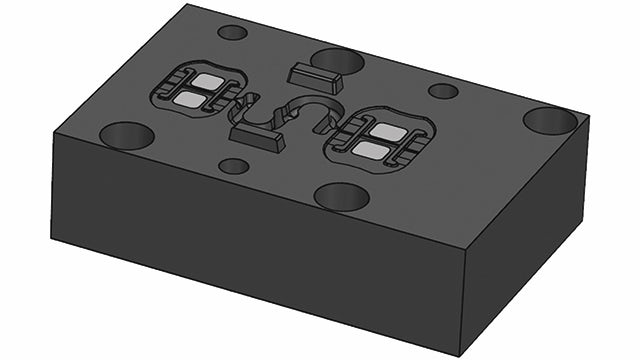

Conventional part versus optimized part.

Conventional part versus optimized part.

The final mold and its plastic part.

The final mold and its plastic part.

MCAM