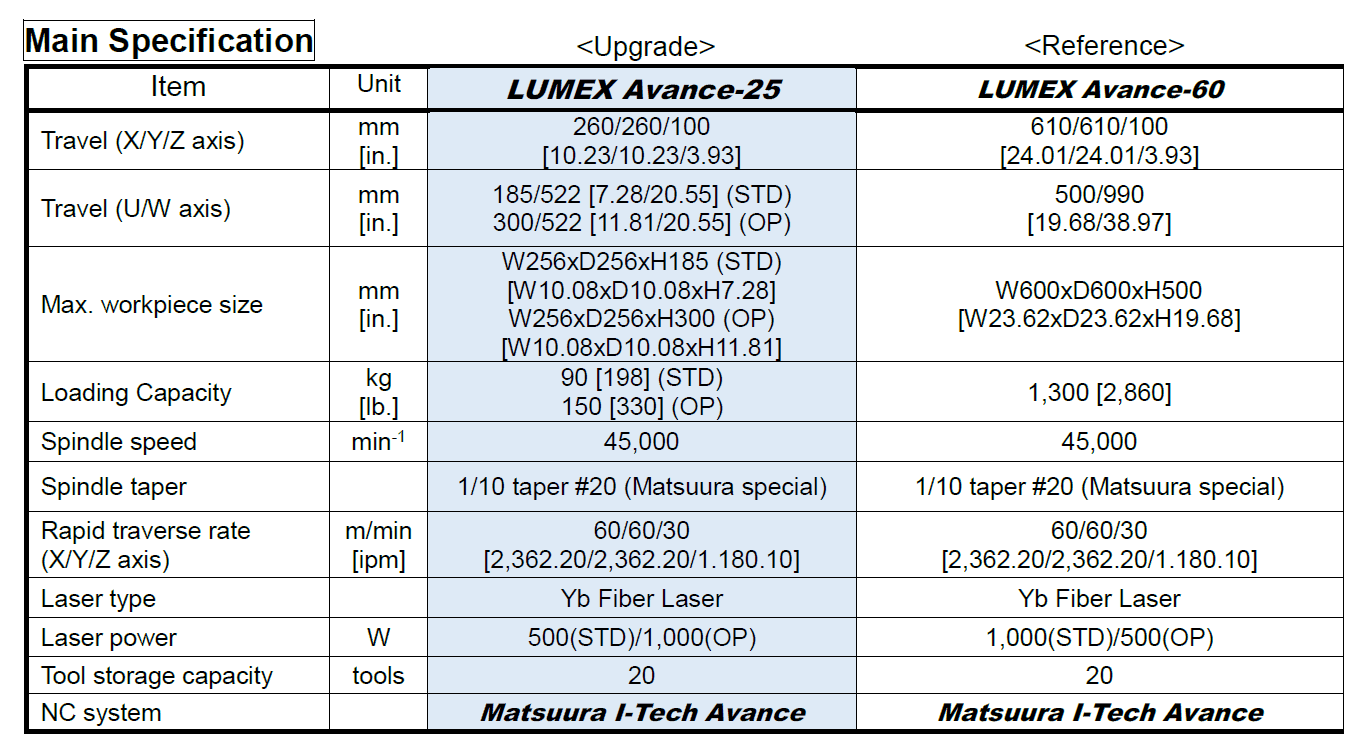

Matsuura Machinery Corporation is pleased to announce the launch of the newly upgraded LUMEX Avance-25, a hybrid metal 3D printer, to further improve productivity and operability.

Matsuura Machinery Corporation is pleased to announce the launch of the newly upgraded LUMEX Avance-25, a hybrid metal 3D printer, to further improve productivity and operability.

LUMEX is Matsuura’s hybrid metal 3D printer series, which comprises metal laser sintering by fiber laser and high-speed milling with a machining center base. Matsuura led the world in 2002 with the commercialization of a hybrid metal 3D printer. By offering greater flexibility in the design, previously not possible in conventional metal milling, Matsuura’s LUMEX Technology reduces lead time and minimizes cost for complex parts, meeting the diverse needs of our customers, who are predominately in the high value-added dies and molds market. (More than 100 machines have been delivered.)

The newly upgraded LUMEX Avance-25 machines have improved productivity and reduced the workload, which are directly linked to the manufacturing cost of AM products. By enhancing the functions of the 5th generation hybrid metal 3D printer (high-speed model), launched in 2017, it has become possible to operate continuously for even longer periods of time.

Matsuura will exhibit the LUMEX Avance-25 at the special event “Additive Manufacturing Area” of JIMTOF2022, the 31st Japanese International Machine Tool Fair, November 8-13 at Tokyo Big Sight.

Main Features:

*Improved productivity by reduction in sintering and milling time

*Productivity improvement by extended unmanned operation

*Reduction of operator workload

Improved productivity by reduction in sintering and milling time

To reduce the sintering and milling time, directly linked to the productivity of customers, the upgraded machine completely reviews the data processing method of the software and minimizes the wait time between operations, achieving a 17.3% reduction in sintering time compared to the conventional model.

Fig. 1. Sintering and milling time comparison between conventional and upgraded machine

*Data is not intended to guarantee the performance.

*Time in reduction (rate of reduction) varies depending on the machine specifications and workpiece size.

Productivity improvement by extended unmanned operation

To improve the machine utilization rate and ensure safe and reliable unmanned night and weekend operation, the newly upgraded LUMEX Avance-25 achieved a reduction in the amount of surplus powder (60% reduction compared to the conventional) and increased in the hopper capacity (conventional 12 liters to 29 liters). By setting the maximum amount of powder in the machine, it is no longer necessary to add powders in the middle and collect excess powder during machine running when building a maximum height 300mm workpiece (including base plate thickness).

In addition, the LUMEX Avance-25 has strengthened the dust prevention measures for the important part of mechanical structure. The protective window cover for laser irradiation is equipped as standard, and by reducing fume adhering and suppressing molding defects, prevents unexpected machine stops and alarms.

The “Operation Status Monitoring Function,” which optimizes production efficiency, and the “Matsuura Remote Monitoring System,” which reduces machine downtime in night/weekend unmanned operations, are available as options.

Reduction of operator workload

To reduce the operator’s workload, the newly upgraded LUMEX Avance-25 offers advanced software to minimize setup time before operation. The capability to load large-capacity projects and handle large-sized and complicated-shaped workpieces, the software can shorten the reading time during data transfer. In addition, direct operation from an external device is possible, and large-capacity projects can be operated with no stress by the available hard disk space inside the machine.

For ease of maintenance, the “Disposable Fume Collector System” is available as an option that enables automatic filter switching. It is possible to operate the machine without interruption and without contact with fumes. This ensures high workability and safe work environment can be maintained. In addition, the machine structure has been upgraded to reduce the workload during machine operation. The Matsuura LUMEX machines achieve the highest accuracy in part fabrication since metal powders are melted and sintered via laser, while surfaces are precisely milled at high speeds. 3D cooling channels can be incorporated into molds in the single setup, thereby increasing cooling efficiency and enabling high-cycle injection molding with better than ever quality and precision, reducing costs, and improving efficiency.

The Matsuura LUMEX machines achieve the highest accuracy in part fabrication since metal powders are melted and sintered via laser, while surfaces are precisely milled at high speeds. 3D cooling channels can be incorporated into molds in the single setup, thereby increasing cooling efficiency and enabling high-cycle injection molding with better than ever quality and precision, reducing costs, and improving efficiency.

According to Tom Houle, Director, LUMEX North America, the hybrid technology is already proven solution for moldmakers. In most cases, the proper implementation of the hybrid technology in a mold component will eliminate the need for EDM.

Molds made in this way can be finished with much greater precision than by using other methods and cooling channels within a die or mold can be arranged in an optimal way, greatly improving the cooling effect of the mold component and improving productivity. Also, the objects produced are strong enough for use as finished products, not just interim molds.

The Matsuura LUMEX was the first machine to combine the two jobs of forming and milling in a single unit. As a result, design and processing times that previously took two weeks to one month can be shortened by a third and costs can be reduced by up to half.

With Matsuura’s Metal 3D Printing, the production of high-volume mold components with conformal cooling and integrated porous venting will minimize the need for traditional EDM processes and provide significant savings to the production of molded plastic components. Matsuura features multiple customer case studies, all showing 25% to 45% reductions in cycle time reductions.

*By implementing the Matsuura LUMEX Avance-25 in their new product development group, a Metal Injection Molding customer reduced their market-entry tooling lead time from 4 weeks to 4 days.

*A high-volume consumer packaging producer utilized the LUMEX technology to address replacement parts and spare component inventory for high-production molds. “Before LUMEX, we stocked $100,000’s of inventory for our molds. We now have reduced our inventory requirement to only the most critical components.”

*A Liquid Silicone Injection Molder employs the Controlled Porosity technology on the LUMEX to reduce tooling development time. “We now provide venting, without the risk of flash, and avoid the previous trial and error, reducing our initial tool development in most cases by more than 80%.”

Learn more about Matsuura’s LUMEX Technology HERE.

Matsuura now offers LUMEX Production Services which benefits Tooling, Injection Molding, CNC Machining, and Die Casting processes and operations. The LUMEX Team will work with you throughout the entire process, including design to help customers fully realize the benefits throughout the life of their products.

Learn more about Matsuura’s LUMEX Production Services HERE.