MAM72: 30 YEARS OF TECHNOLOGICAL INNOVATION

In 1991, Matsuura introduced a new corporate motto: “Humans, Earth, and Technology.” This motto represented our individuality and our respect for employees, customers, and the Earth.

The objective was to put people first, while at the same time striving to be a global company helping to create a better future through its products.

In 1991, predicting the need for reducing working hours, Matsuura developed the 5-axis MAM72 series capable of unmanned operation for 72 consecutive hours and ushering in and defining a new age of unmanned palletized and fully automated pallet pool CNC machining production.

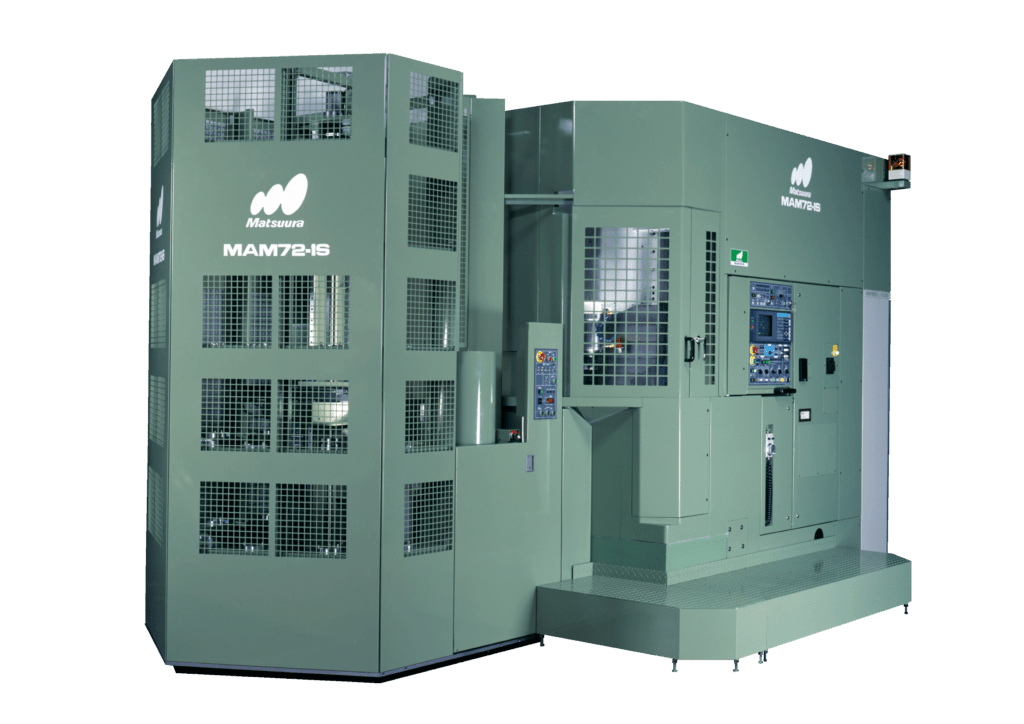

In the beginning of Japan’s Heisei Era, regulations on working conditions in manufacturing put strict controls on overtime work and annual working hours. The MAM72-1S was developed in response to this movement and offered reduced setup time and a cell system for unmanned operation, improving conditions for workers without sacrificing production.

1991

MAM72-1

- Space-saving multi-pallet system.

- 72 consecutive hours of unmanned operation.

- Reduction of total annual labor hours.

1999

MAM72-3VS

- 5-Axis + multi-pallet system (40 pallets)

- 72 consecutive hours of unmanned operation, capable for high-mix, low-volume production

- work size dia. 300mm

2003

MAM72-63V

- Large 5-axis machining center (max. work size dia. 630mm)

- Multi-pallet system (2/6/18 pallets)

2004

MAM72-25V

MAM72-25VPC10

- Small 5-axis machining center (max. work size dia. 250mm)

- Multi-pallet system (2/10 pallets)

2006

MAM72-42V

MAM72-42VPC5

- Mid-size 5-axis machining center (Max. work size dia. 420mm)

- Multi-pallet system (5 pallets)

2010

MAM72-100H

- Max work size dia. 1,000mm

- 4/5th axis direct drive motor

- Multi-pallet system (6 pallets)

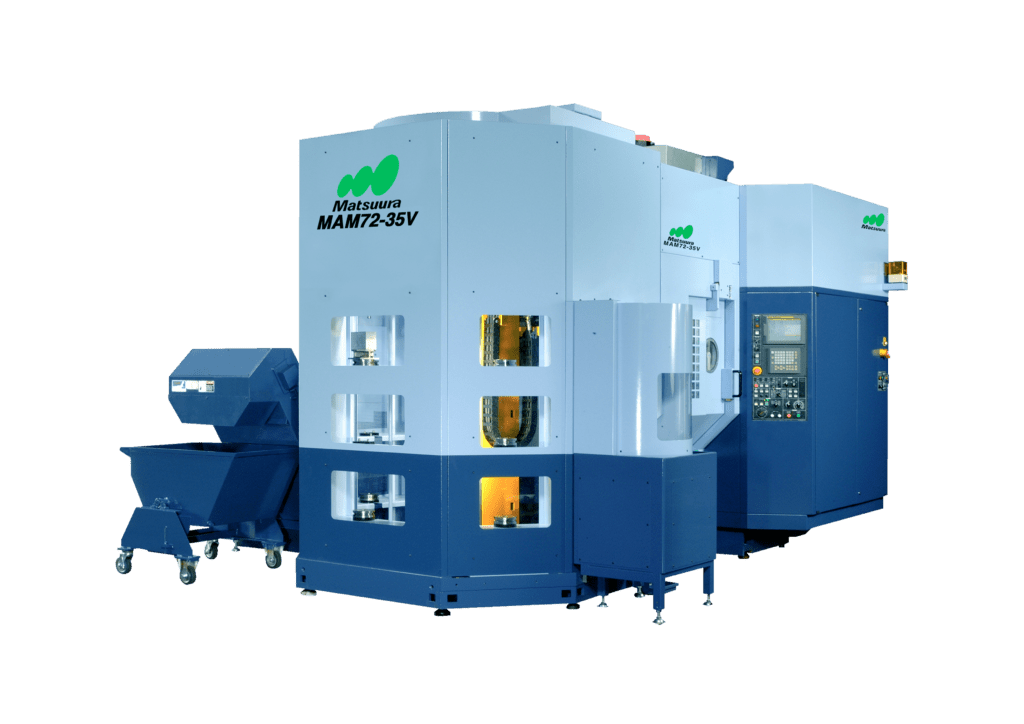

2012

MAM72-35V

- Upgraded functions.

- 4/5th axis direct drive motor.

- Multi-pallet system (2/32/40 pallets)