Join Matsuura USA at Productivity’s 21st Biennial Oktoberfest Tool Show, September 21-23 in Plymouth, MN.

Join Matsuura USA at Productivity’s 21st Biennial Oktoberfest Tool Show, September 21-23 in Plymouth, MN.

Productivity Inc. will showcase: the NEW Matsuura MAM72-52V high speed, large capacity 5-axis vertical machining center; the MX-850 5-axis vertical machining center configured with 4 pallets and up to 120 tools; and the MX-330 5-axis vertical machining center, offering an easy transition from 3-axis to 5-sided or 5-axis production.

Productivity’s Oktoberfest Tool Show is one of the Midwest’s largest CNC Machine Tool Trade Shows. This year’s show will feature an array of new technology in machine tools, robots, tooling and accessories, measurement solutions, and contract dimensional inspection services.

Attend live machine demos, valuable seminars, talk to metalworking experts, enter prize drawings, and enjoy the food and music.

Register HERE to be automatically entered into a drawing to win 1 of 10 Yeti coolers valued at $300.

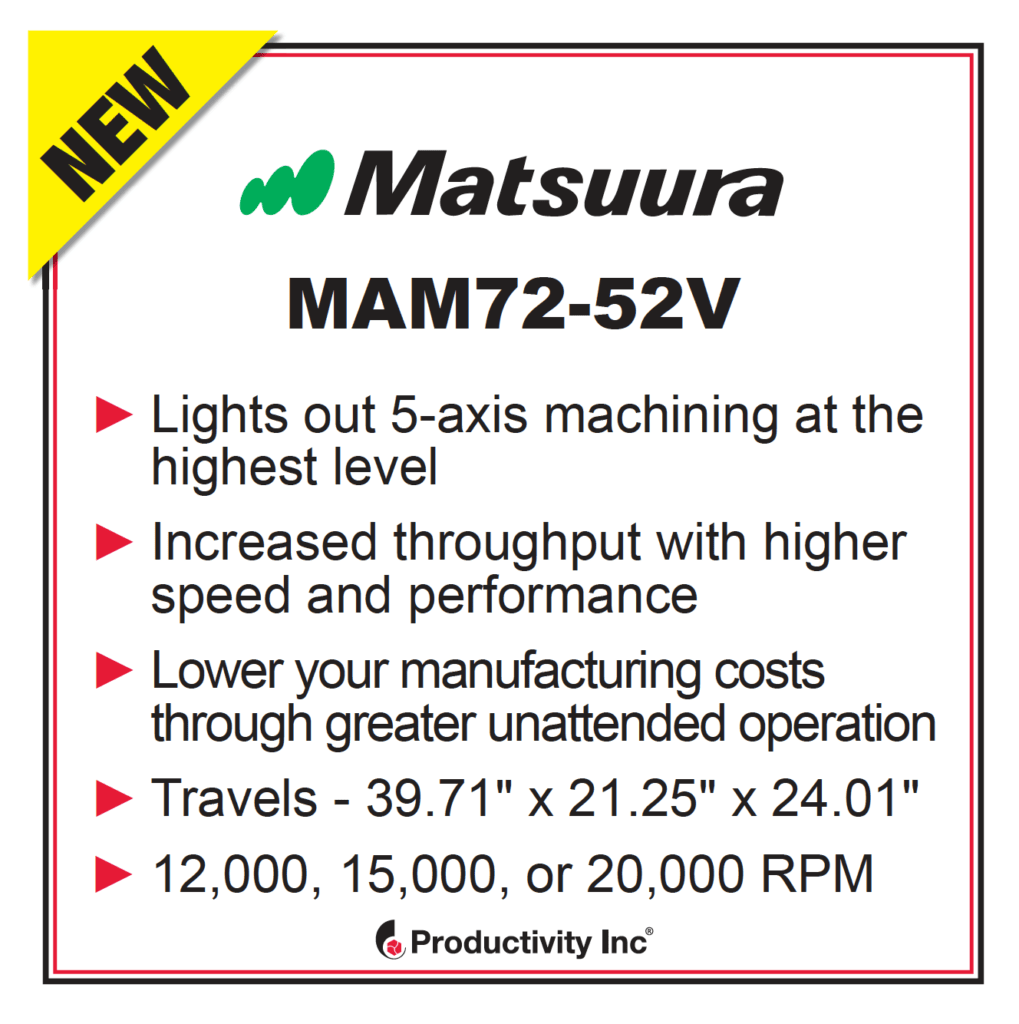

Matsuura’s MAM72-52V was designed to handle a greater workpiece size than existing models, offers faster response times to market and delivers even higher productivity to meet customers’ business requirements for faster cycle times and cost down performance.

Matsuura’s MAM72-52V was designed to handle a greater workpiece size than existing models, offers faster response times to market and delivers even higher productivity to meet customers’ business requirements for faster cycle times and cost down performance.

The MAM72 series originated the concept of the tower pallet system and remains unrivalled in the marketplace. Achieving process integration, complex 5-axis machining, and versatile functionality in all machining environments, variable-part variable-volume production and reliable extended unmanned operation are a standard feature of the MAM72 series.

With the new MAM72-52V, the maximum workpiece size is 520mm x 400mm with a load capacity of 300kg per pallet: a 23% increase in diameter, 50% increase in weight, and 75% increase in envelope volume compared to existing models.

In addition, the newly developed 4th-/5th-axis table equipped with direct drive motors achieves a rapid traverse rate of 50min-1 and 100min-1 respectively, enabling both high speed and high accuracy in one machine. By reviewing the machine structure, improved accessibility and good operability for setup are ensured since the distance from the machine front (oil pan edge) to the pallet center is reduced to 564mm and that to the spindle center to 134mm.

The MAM72-52V is an all-in-one machine that enables variable-part variable-volume production and extended unmanned operation, featuring a matrix tool magazine (130 tools/330 tool magazine base), tower pallet system (PC15) and chip removal system (spiral chip conveyor, lift-up chip conveyor) as standard.

The new machine is Internet of Things (IoT) ready, delivering measurable remote and real-time monitoring of the machine status, condition, and performance.

Learn more about the MAM72-52V HERE.

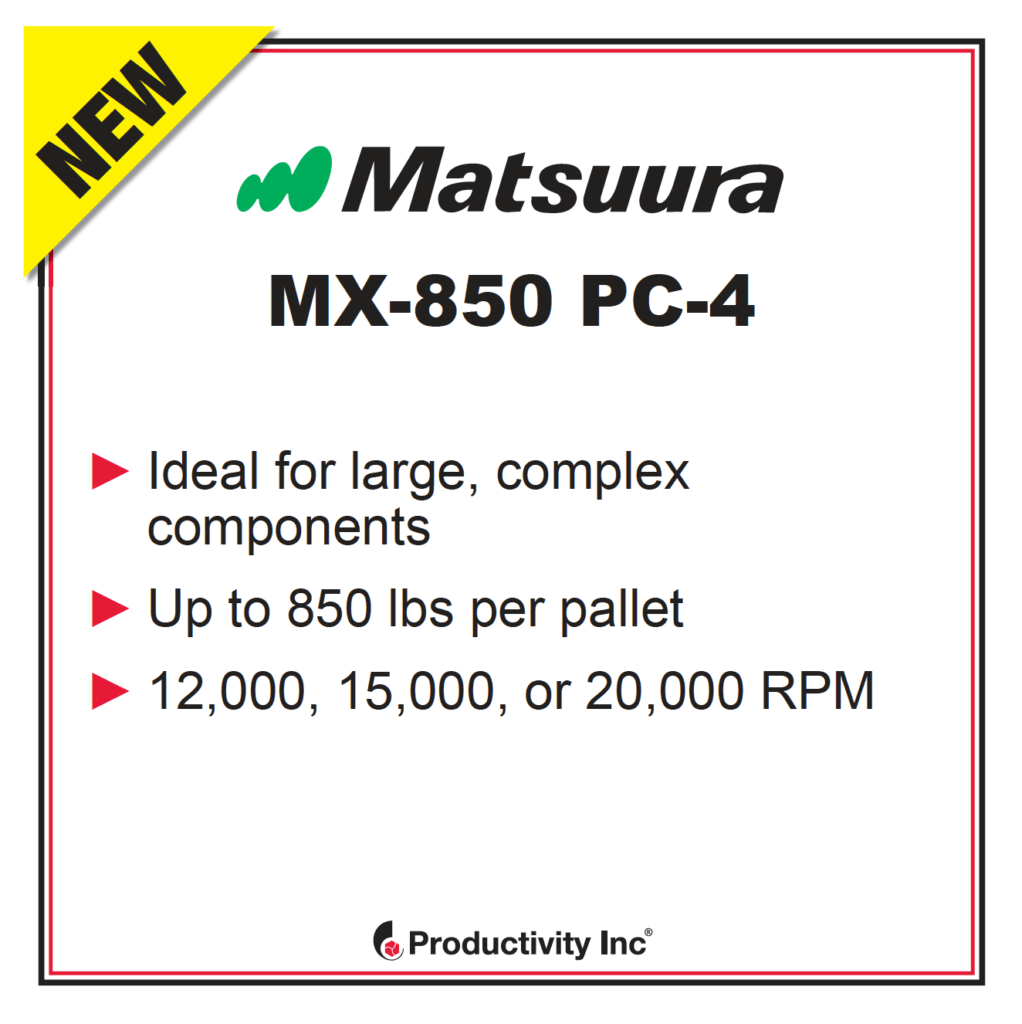

The MX-850 PC4, an automated version of the large capacity 5-axis vertical machining center, is configured with 4 pallets and up to 120 tools for extended periods of unmanned machining of large and complex components and billets, the PC4 can accommodate 400kg per pallet and a workpiece size of Ø850mm x 450mm.

The MX-850 PC4, an automated version of the large capacity 5-axis vertical machining center, is configured with 4 pallets and up to 120 tools for extended periods of unmanned machining of large and complex components and billets, the PC4 can accommodate 400kg per pallet and a workpiece size of Ø850mm x 450mm.

Developed in response to market demand for a large capacity, high quality, yet cost effective single table Matsuura 5-Axis machining platform, the MX-850 is compactly built, yet ensures high rigidity and a sufficient machining area and workability.

The MX-850 is equipped with Matsuura’s proven operating system optimizing performance, automation, and spindle utilization. The operating system permits direct, instinctive control as well as MIMS (Matsuura Intelligent Meister System) and Matsuura’s proprietary Intelligent Protection System for the prevention of collisions.

Learn more about the MX-850 PC4 HERE.

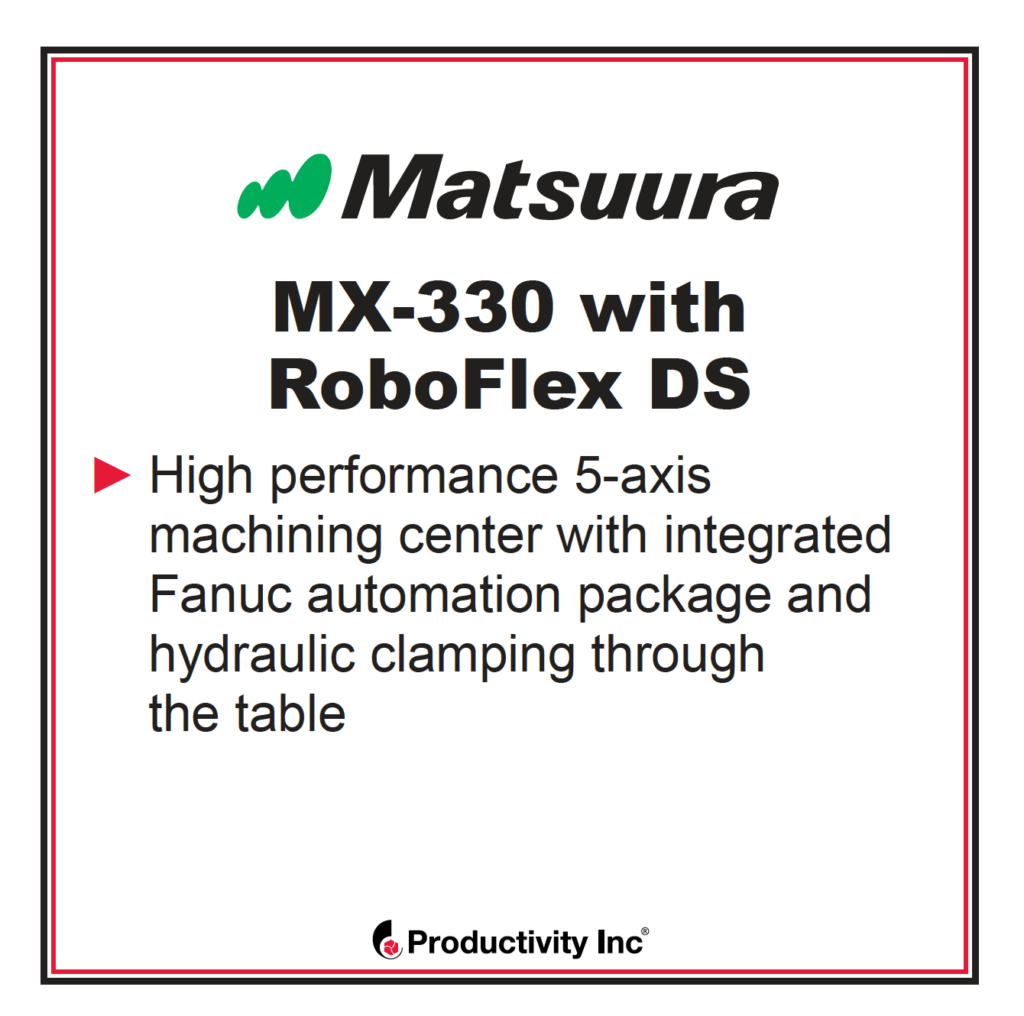

Matsuura’s MX-330 5-axis vertical machining center delivers machining center versatility with a standard Matsuura-made high accuracy spindle of 15,000 RPM with 48 ft-lbs. of torque. Optional 15,000 RPM with 88 ft-lbs. of torque and 20,000 RPM with 80 ft-lbs. of torque are available.

Matsuura’s MX-330 5-axis vertical machining center delivers machining center versatility with a standard Matsuura-made high accuracy spindle of 15,000 RPM with 48 ft-lbs. of torque. Optional 15,000 RPM with 88 ft-lbs. of torque and 20,000 RPM with 80 ft-lbs. of torque are available.

Ideal for the medical and aerospace industries and other high precision components, the MX-330 offers an easy transition from 3-Axis to 5-sided or 5-axis production and is compactly built requiring floor space of only 6.1 ft. wide by 10 ft. long to ensure high-rigidity with a generous machining area and a table loading capacity of 177 lbs.

The machine’s maximum work envelope is D330 mm x H300 mm, with an optional D420 mm x H 300 mm. The MX-330 is designed with a RAM type structure, which offers a compact and highly durable machining platform. Available tool magazines include standard 30 tool drum and optional 60 and 90 tool chain.

The MX-330 comes standard with a FANUC 31iMB with PANEL-I Control. The FANUC31iMB with PANEL-I Control is designed to be extremely user-friendly by making operating CNC machines easy and efficient.

Learn more about the MX-330 HERE.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information about Matsuura, please contact: [email protected] or visit: HERE.