St. Paul, MN (July 16, 2019) — According to Doug Noxell for Moldmaking Technology Magazine, purchasing the right tools for manufacturing dies and molds can save considerable time and money down the line, regardless of the upfront cost. There are many factors that affect the real cost of ownership—ranging from financing and resale value, uptime and operation efficiency to consumable tooling costs and reduced secondary operations to improved accuracy. Older technology will impede your business in a competitive global market.

St. Paul, MN (July 16, 2019) — According to Doug Noxell for Moldmaking Technology Magazine, purchasing the right tools for manufacturing dies and molds can save considerable time and money down the line, regardless of the upfront cost. There are many factors that affect the real cost of ownership—ranging from financing and resale value, uptime and operation efficiency to consumable tooling costs and reduced secondary operations to improved accuracy. Older technology will impede your business in a competitive global market.

Implementing the Right Strategy

To be successful, you first must eliminate as much labor and as many operations as possible. By having the correct tools, whether cutting tools, the machine itself and/or the software, these items are necessary for the speed and accuracy required in today’s market. If you can do all of this and run unattended, then your cost will go down and the better quality and accuracy will go up as a result.

THE BOTTOM LINE IS MAKING A BETTER PRODUCT FOR THE CUSTOMER.

Simply put, the older the technology, the more manual labor is used which costs more money in the long run. Whether the labor is in operating the machine, secondary operations such as polishing or hand work, the best way to reduce costs and get the piece delivered more quickly is to cut as much manual labor as possible.

The older technology refers to CNC machines usually eight or more years old with slower rpms and that have no software on the machine to control acceleration and deceleration. This doesn’t mean that there aren’t new machines still made using this outdated technology. Making large heavy cuts at slow feedrates was the norm at one time. However, the slower spindles with the higher horsepower cause poor tool life and poor surface finish. Old-style toolholders include ER collets systems and the endmill holders with set screws. The runout and balance on these holders are not suitable for tool life or surface finish.

That is when it’s time to replace that outdated CNC with a new or high-end machining center with features that create labor cost savings using toolchangers, tool lasers and proper cutting techniques, which means more volume with the same staff.

In a typical production-type environment, cost justification for a per-part piece is black and white: A shop needs to produce X many parts, so they purchase X equipment. However, in a moldmaking environment, it’s much more difficult because the product goes through many different areas throughout the shop.

If you look just at the machining portion, faster is not necessary cost efficient. It’s not just the hours on the machine; it’s all the secondary hours or operations such as EDM or polishing that need review. The true cost of ownership is the total cost to produce your mold insert and that includes how much money is saved reducing secondary operations.

Breaking Down the Cost

For example, if you currently machined a core or cavity insert on your traditional CNC machine in 50 hours at $65 an hour ($3,250) and added approximately $300 for consumable tooling costs, two days of polishing (16 hrs X $50/hr) at $800 and one day of spotting at $400 (8 hrs x $50/hr) your total cost for production would total $4750. Investing in newer technology would reduce your production costs by 25 percent by decreasing machine hours to (30 x 100 = $3000), consumable tooling costs to $200 and spending fewer hours polishing (5 hrs x $50 = $250) and spotting (2 hr x $50/hr = $100).

With the new technology the total cost would be reduced to $3450.

The consumable tooling lasts longer when used in the higher quality machines. The simple fact that you spend less time changing tools is a savings not to mention the ability to cut an entire part with one tool for 20 or 30 hours with no blends from tool wear.

If EDM is required, it may be possible to machine these details using newer equipment for even further savings. When companies try to cut ribs and small features with older technology, it is not cost efficient due to the existing machine quality. The new high-speed machines are capable of cutting very small details that were previously produced using EDM.

With current technology, the finish and accuracy that will allow that mold to be closed and spotted together (sealed off to make the part) will happen much quicker. Years ago, a mold was put into a spotting press and one to two days were spent hand-grinding and fitting the mold together. Now when these parts are cut to the necessary accuracies, it’s down to hours instead of days. That is significant. Knocking two days off your delivery time saves you time and money.

Running a machine unattended, overnight may not provide a cost savings if the older technology is only running one tool to complete the job. Some shops claim that they are doing lights-out with their older machines; however, it is just because their programs took so long to run. They leave the machines running, but at a reduced feedrate to be safe, etc. The shops believe they are getting something for free—even though it is a very low productivity level compared to the true, unattended, lights-out facilities that are talked about today.

Examining Finance Costs

When it comes to looking at finance costs, purchasing a higher quality machine will lower the monthly payment because the finance company will usually offer a higher residual compared with the less quality machines based on the true resale value.

Time to Buy

Depending on the status of the equipment, it is recommended to purchase at least one new piece of equipment if you are currently using outdated technology and replace current technology every two to three years.

If you have a quality piece of equipment that is only two to three years old, it holds its value very well. When it’s time to upgrade, it’s very easy to trade up—much like leasing your car. The people who don’t invest in newer technology just cannot compete and they may slowly die off. Those who do invest seem to stay busy, and thus competitive.

Summary

Essentially, if you want to stay with the new machine technology because it is giving you all of these added features, and if you keep flipping these machines over every three years, you’ll find that the cost will go down over time, because you are just paying the difference between the two. Trying to replace five machines at a time is a very large investment to make at one time which is not cost-effective for most small mold shops.

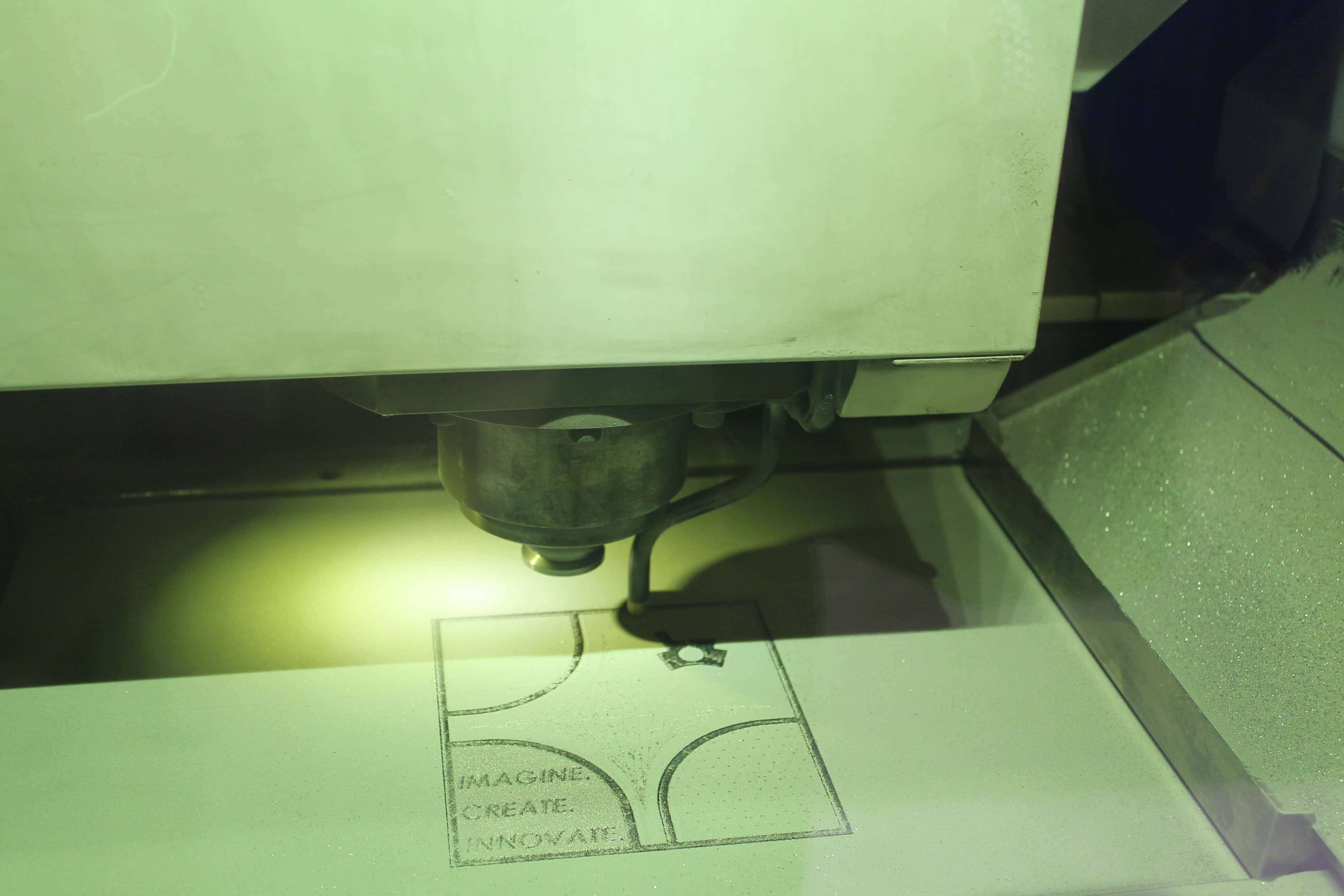

Matsuura Machinery’s LUMEX-brand hybrid additive machine, a combination three-axis machining center and metal powder bed printer designed specifically to produce conformally-cooled molds and mold inserts. As with other powder bed machines, the LUMEX builds parts one layer at a time from the bottom up, but the addition of a high-speed milling spindle means those layers can be machined as needed for accuracy and surface finish.

More efficient molds and moldmaking may have been the machine designer’s original intent, but the LUMEX is garnering interest from a number of additional industries—including medical, aerospace, and tooling manufacturers—for its ability to do what traditional powder bed machines can’t: produce extremely accurate parts and part features.

Still, there’s no arguing that the LUMEX offers significant benefits to its target audience. “The return on investment is really threefold,” says Tom Houle, Director of Matsuura LUMEX, NA. “First off, additive manufacturing allows moldmakers to create conformal cooling channels and porous venting, both of which improve mold efficiency. Secondly, the ability to build a production tool in days versus weeks or months is obviously a huge gamechanger for anyone in this industry. And finally, those toolmakers who are also injection molders are reaping the additional benefits of cycle time savings, reduced capital expenditure, and molds that are less expensive to run day after day.”

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information on Matsuura products, contact: [email protected] or visit: www.matsuurausa.com.