St. Paul, MN — (July 2, 2019) From Additive Manufacturing Magazine’s video- Stephanie Hendrixson, Senior Editor and Pete Zelinski, Editor-In-Chief.

According to Hendrixson and Zelinski, the place for additive is at the beginning of the conversation, at the beginning of the design process and one main reason for utilizing the technology is in conformal cooling, particularly in molds. In conformal cooling, straight drilled holes for cooling are not required, but instead grow the cooling channels internally to follow the contours of the form.

According to Hendrixson and Zelinski, the place for additive is at the beginning of the conversation, at the beginning of the design process and one main reason for utilizing the technology is in conformal cooling, particularly in molds. In conformal cooling, straight drilled holes for cooling are not required, but instead grow the cooling channels internally to follow the contours of the form.

See the entire video HERE or read the full transcript below:

Stephanie Hendrixson: Is additive manufacturing the same as 3D printing?

Peter Zelinski: Additive manufacturing is the approach to manufacturing that has 3D printing at its heart. If I am 3D printing, I am not necessarily manufacturing, and additive manufacturing begins with 3D printing, but it includes more than that. So ultimately, these are different terms and the difference is significant.

Stephanie Hendrixson: Are 3D-printed parts as good as those made through injection molding or machining or some other type of conventional technology?

Peter Zelinski: It depends. If what you want is a near-net-shape part, 3D printing is better. It will get you nearer to net shape than casting or forging will.

I think you’re asking a question that’s more fundamental than that: Can 3D printing produce a useful, functional part? The answer is, unequivocally, yes. Additive manufacturing is an option that’s on the table now for making a tool or making an end-use production part.

Stephanie Hendrixson: In what situations does additive make the most sense?

Peter Zelinski: The reason to use additive often has to do with realizing a geometrically intricate form that you couldn’t get any other way, and then there are all these other reasons to use additive as well. So help me out—let’s rattle off use cases for additive:

Consolidating an assembly. Take a component that’s formerly an intricate assembly of lots of little pieces and just 3D print that as a single complex part.

Stephanie Hendrixson: Lightweighting, the ability to place the material only where you need it, to fill a solid form with a lattice structure, and not carry that extra weight.

Peter Zelinski: Conformal cooling, particularly in molds. Don’t have straight drilled holes for cooling but instead grow the cooling channels internally to follow the contours of the form.

Stephanie Hendrixson: Low volumes of parts. If you only need one or 50 or 100 of something, maybe you can 3D print it instead of putting that investment into a mold.

Peter Zelinski: Making tools. A tool is often a one-off part that’s got a lot of complexity in it, and commands a lot of lead time. Make that tool additively.

Stephanie Hendrixson: Customization, when you have a product that requires some level of personalization. Maybe it’s a medical implant and you want to make it the exact right size for that patient.

Peter Zelinski: Topology optimization. Allow software to grow a part form digitally based on the loads that it requires so that you use only the mass and material needed.

Stephanie Hendrixson: Repair applications. If you have a part that has seen a lot of wear, you can rebuild the portion of it that’s missing.

Peter Zelinski: I think there’s another way to face this question as well: The best use of additive ultimately is to realize a shape, a form that you didn’t think you could make or solve a problem that you didn’t know you had.

So, what’s the place for additive? The place for additive is at the beginning of the conversation, at the beginning of the design process.

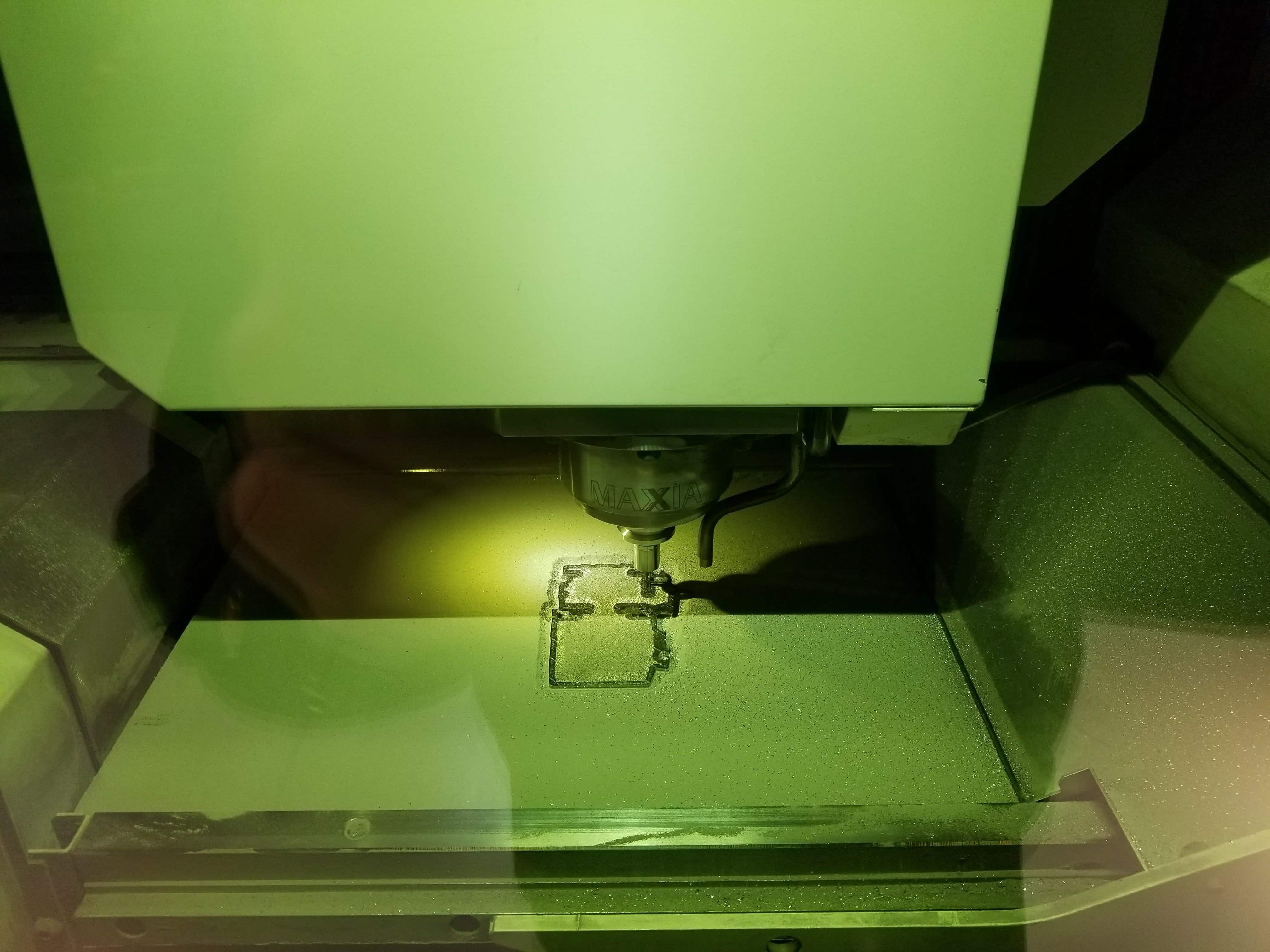

Matsuura’s LUMEX Technology relies on one-machine, one-process manufacturing of complex molds and parts by fusing metal laser sintering technology with high speed milling technology. The Hybrid technology creates a “finished” part with machined surface finish and accuracy, without inducing the additional variation caused by multiple machine set-ups and part handling.

According to Tom Houle, Director, LUMEX NA, Matsuura’s Hybrid additive/subtractive machining produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. This technology allows the ability to “grow” a metal component in layers with complex internal features and fine mill those internal features, as the layers are added, to give a perfect surface finish are what makes the LUMEX Series such a distinctive, unique and remarkable production platform and machine tool.

Houle explains that the hybrid technology is a proven solution for moldmakers. In most cases, the proper implementation of the hybrid technology in a mold component will eliminate the need for EDM. This in and of itself is a large time saver in the mold build process. Many components can be completely machined in the hybrid machine, there is an elimination of queue times to get other work completed on a component, typically reducing overall mold build time.

Houle believes the benefit to the owner of the mold is clear: improved cycle times, sometimes as much as 50 percent using conformal cooling, and improved part yields and initial part quality by utilizing the variable porosity capabilities of the powder bed fusion process to assist in the venting of mold gases in the flow front. The Matsuura LUMEX Technology has completely disrupted the part design paradigm. Instead of starting from a block or some other traditional geometric shape, the designer now begins with a blank page to ‘grow’ their designs for lightest weight, sleekest design, and most efficient use of material.

The use of the term, “sintering” is a generic description of the process that most Metal AM machines use. The technology utilized in the Matsuura LUMEX series is more accurately described as Powder Bed Fusion with “selective laser melting.” For the Hybrid technology, this machine configuration provides the most benefits and allows the user to capitalize on the unique features that can be created with the Matsuura LUMEX Hybrid.

The Matsuura LUMEX technology complements the milling process by utilizing Powder Bed Fusion. This technology provides excellent stability and repeat-ability, which allows the machine to know where in the coordinate system the build is taking place and maintain the overall accuracy of the completed part.

The ability to “grow” a metal component in layers with complex internal features and fine mill those internal features, as the layers are added, to give a perfect surface finish are what makes the LUMEX Series such a distinctive, unique and remarkable production platform and machine tool.

For more information on the Matsuura LUMEX Technology, please contact the team at: [email protected].

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura products, contact: [email protected].