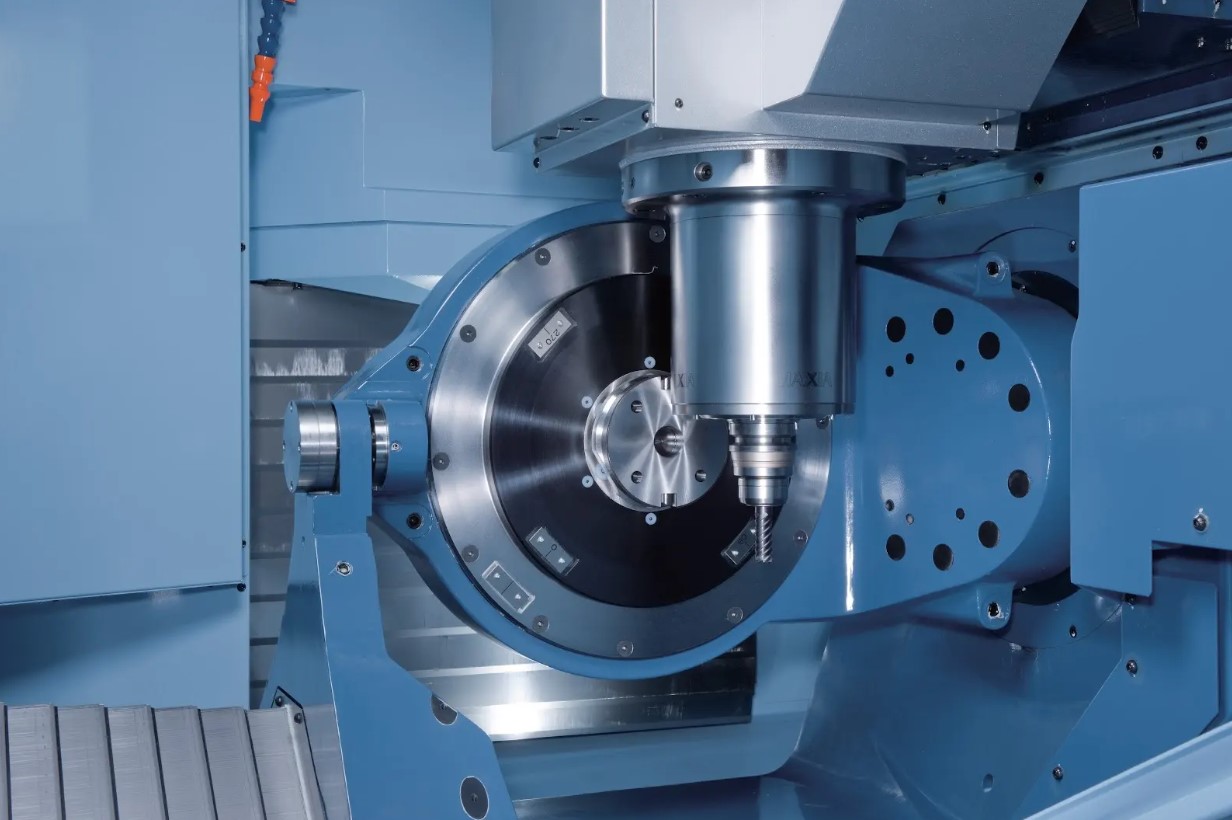

P&F Machining in Otsego, MN utilizes innovative business practices and the latest in 5-axis cnc technology to provide customers with ‘Best in Class’ quality, delivery, and customer satisfaction. P&F employs a Matsuura MAM72-25V 5-Axis Vertical Machining Center to achieve their high customer commitment.

P&F Machining recently published the case study below showcasing their Matsuura 5-axis machine:

How the Matsuura MAM72-35V Elevates Complex Part Manufacturing

The Matsuura MAM72-35V 5-axis machining technology is a powerful solution for industries requiring high precision and efficiency. This machine’s advanced capabilities make it particularly well-suited for handling intricate designs, reducing setup times, and achieving superior quality in complex parts.

Mastering Intricate Designs with 5-Axis Machining

One of the key advantages of the Matsuura MAM72-35V is its ability to work with intricate and geometrically complex designs. In industries like aerospace, where parts often require precise angles, curves, and intricate details, traditional 3-axis machining can struggle to achieve the necessary results. The 5-axis technology of the MAM72-35V allows simultaneous movement along five axes, enabling the cutting tool to approach the workpiece from virtually any angle. This flexibility is critical for creating complex geometries in a single setup, minimizing the need for additional machining operations.

For example, in aerospace, the manufacture of components like turbine blades, engine parts, and airframe sections require extreme precision to ensure optimal performance and safety. The MAM72-35V’s ability to perform high-speed, multi-axis machining enables it to produce these parts with tight tolerances and smooth finishes, meeting the stringent quality demands of the industry.

Reducing Setups for Greater Efficiency and Fewer Errors

Tool changes and setup times can significantly degrade the efficiency of an operation, particularly in industries that deal with large production volumes or time-sensitive projects. The Matsuura MAM72-35V addresses this challenge by significantly reducing the need for multiple setups. Thanks to its 5-axis capabilities, complex parts that would traditionally require several repositioning steps and setups can now be machined in a single run. This not only saves time but also reduces the potential for human error and improves repeatability.

To boost productivity and efficiency even more, Matsuura has packed this machine with a 32-pallet capacity for extended unmanned operation, and incorporated a 60-tool changer, upgradeable to 530-tools. The ability to streamline production with minimal setup is invaluable. The MAM72-35V enhances production speed without sacrificing precision, making it a crucial asset in meeting the high demands of high-precision manufacturing.

The Bottom Line

With its advanced 5-axis technology and impressive features, the Matsuura MAM72-35V is an ideal solution for high-volume, high-precision manufacturers seeking to enhance productivity, reduce setup times, and still handle intricate designs. Its ability to manage complex parts squarely positions it as a key player in modern, high-tech manufacturing processes. Efficiency, they say, is the key to profitability in machining. With the Matsuura MAM72-35V on the job, you’ve got a great head start.