St. Paul, MN (November 2, 2020) – Covid-19 is not just a global pandemic and public health crisis. Industries around the world are adjusting to a new normal, but normal is no longer an option, according to Robotics and Automation News.

St. Paul, MN (November 2, 2020) – Covid-19 is not just a global pandemic and public health crisis. Industries around the world are adjusting to a new normal, but normal is no longer an option, according to Robotics and Automation News.

Strict social distancing rules have left many manufacturing businesses with fewer staff and, in some countries, these industries have had to close their doors to try and flatten the curve of infections.

Switching production on and off is not an easy or affordable task.

The new reality is complex and uncertain, and organizations will need to adapt to survive and thrive. The impact of social distancing within an industrial environment means that leaders need to look to automation to lessen the blow of reduced operational capacity of their shift workers.

With the right machinery and equipment, the Machining & Manufacturing industries can mitigate against the issues that arise from fewer staff being able to work.

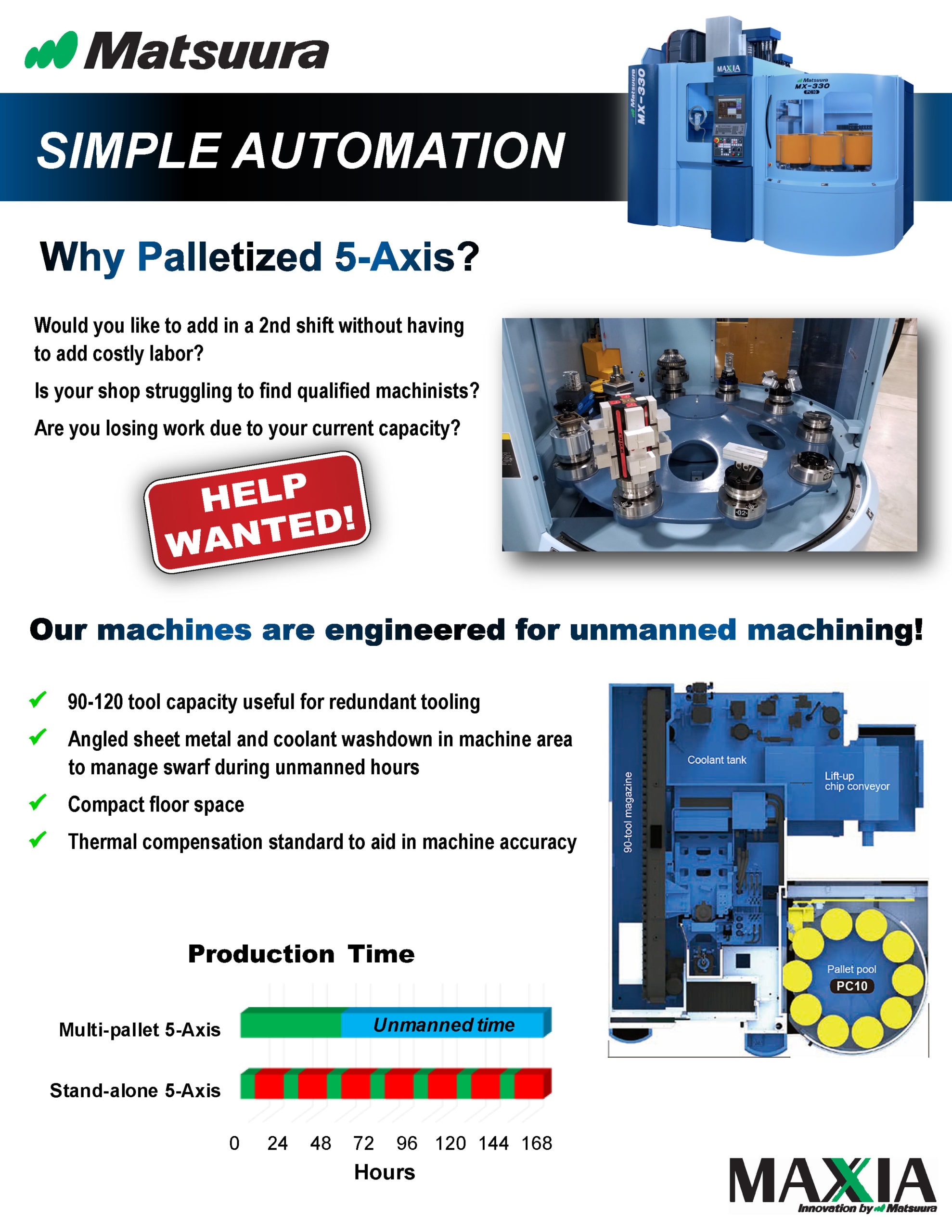

For many machine shops today, the most promising avenue of potential expansion is not a new market or an addition to their facilities, but instead the untapped, unstaffed nighttime hours that could be captured for automated, “lights-out” production.

A machining center better suited to realize significant unattended production combines five-axis or five-sided machining to complete or nearly complete a part in a single cycle, along with pallet loading in order to enable a queue of work to be set up and staged for the machine. Matsuura’s U.S. president Craig St. John says demand for automated machining centers such as this has never been higher.

A survey from Thomas.net examined the impacts of COVID-19 on the industrial sector, revealing one in four U.S. manufacturers are considering expanding industrial automation as a result of COVID-19, while one in five already has automated systems in place.

Matsuura’s original automation and unmanned running systems provide solutions for organizations facing labor shortages by utilizing working hours effectively. With the deficiency in skilled labor to operate CNC Machines, automation provides the potential for expanding production and increasing profit while decreasing employment costs.

Matsuura’s systems can be installed as an option for Matsuura’s 3-axis/5-axis machining centers to automate tool changes and pallet changes using programs, drastically improving the productivity.

Installing ATC tool magazines and APC pallet systems as options with Matsuura 5-axis machining centers allows the machines to automatically continue production without human intervention, even during the night.

Matsuura’s customers often run the high-mix, low-volume components which require more engineering and set-up during the business day. Then, they change over to the unmanned production, where the pallets in the system run all night.

CNC machining is a perfect example of how to increase product quality while simultaneously increasing production speed and efficiency.

The cost-effective nature of CNC machining has the operator working from an acceptable social distance to any other staff member and often behind a guard or closed door as an added safety precaution.

More from Robotics and Automation News: https://roboticsandautomationnews.com/

Please contact your exclusive Matsuura Distributor to learn more.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Matsuura, an innovator in the design, development and manufacture of high-precision manufacturing solutions for more than 80 years, has been the forerunner in designing pioneering technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business.

For more information about Matsuura, please contact: [email protected] or visit: matsuurausa.com.