St. Paul, MN (September 19, 2018) — (Customer Testimonial provided by CAMPlete)

Mission Tool is a dynamic business that specializes in precision stamped and machined components. A key to 50 years of success for Mission Tool is their capabilities to suit every need, ensuring quality and precision from blueprint to finished product for every single customer. MTM now employs over 50 employees in their 30,000 Square foot facility.

One of these employees is Engineering Manager, Dave Decker. Decker has been at MTM for 5 years now, with one of the major reasons for him being brought in being the companies move into 5-axis machining. The “forward progression” at MTM was one that according to Decker, was “written on the wall”. A long time Matsuura shop, it was time for an upgrade, therefore in 2015 MTM upgraded to two Matsuura MAM 72-63V’s.

When deciding on posting and verification software, TruePath was the inevitable choice. Noting, “After seeing videos of the software in action it looked like other verification software’s on the market, and then some, it was kind of a no-brainer.”

When asked about the impact TruePath has had at MTM, Decker noted the time savings it provides. Stating, “when I hit post it’s done, and I know it’s done. I just need to take the posted file from the machine and stick it in the fastems.” These time savings have had an impact not just on how MTM operates their shop, but also how fast they are able to turn around completed parts.

Decker added, “We have been told several times by customers that they like that we think outside the box. We are able to think like this largely because CAMplete TruePath allows us to see parts in ways that we otherwise would not be able to.”

Learn more about Mission Tool at their website here: https://missiontool.com/

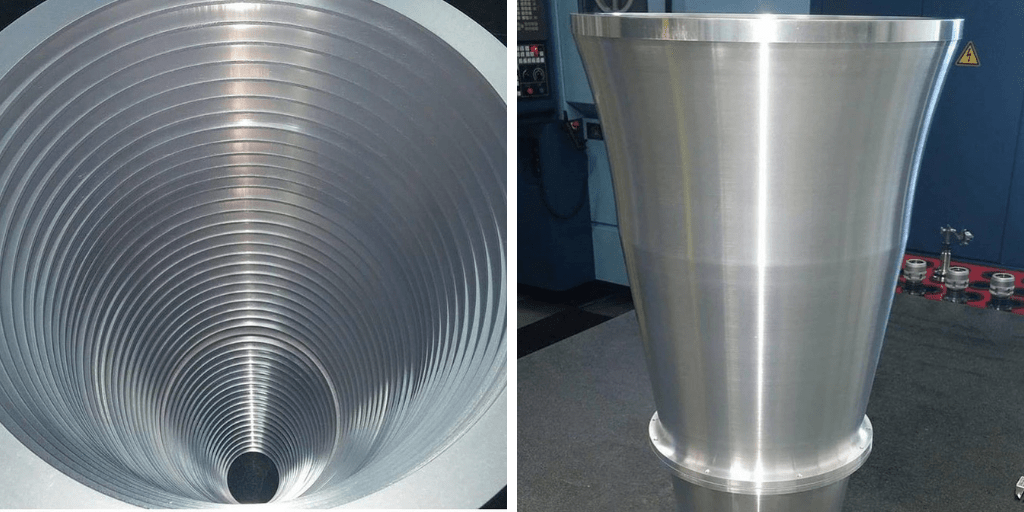

The Matsuura MAM72-63V 5-Axis Vertical Machining Center features high-accuracy and complex five-axis machining for large and geometrically complex components requiring simultaneous high-speed and high-accuracy 5-axis machining.

The MAM72-63V delivers long periods of unmanned productivity and allows the machining of larger components with a single operation. The MAM72-63V lowers production costs by eliminating part setups, handling and material waste.

With the Matsuura MAM72 Series of fully automated machining, identical components are produced while human error in production is effectively eliminated. All components can be machined with absolute accuracy.

Enhancing cost-savings and providing better positioning with a reduced setups, the MAM72-63V provides pallet and productivity solutions to keep your work center efficiently producing components around the clock. The Matsuura MAM72-63V offers an array of configurations and a 40-taper Matsuura Hi-Tech MAXIS Spindle providing unequaled cutting performance.

Like all Matsuura 5-axis CNC Machines, CAMplete TruePath came standard with Mission Tool’s MAM72-63V. This relationship between Matsuura and CAMplete, offered a complete solution of software and hardware that allowed Mission Tool to hit the ground running from day one.

To learn more about CAMPlete, please visit: CAMPlete.com

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura products, contact: [email protected] or visit: www.matsuurausa.com.