(MachiningNews.com)

(MachiningNews.com)

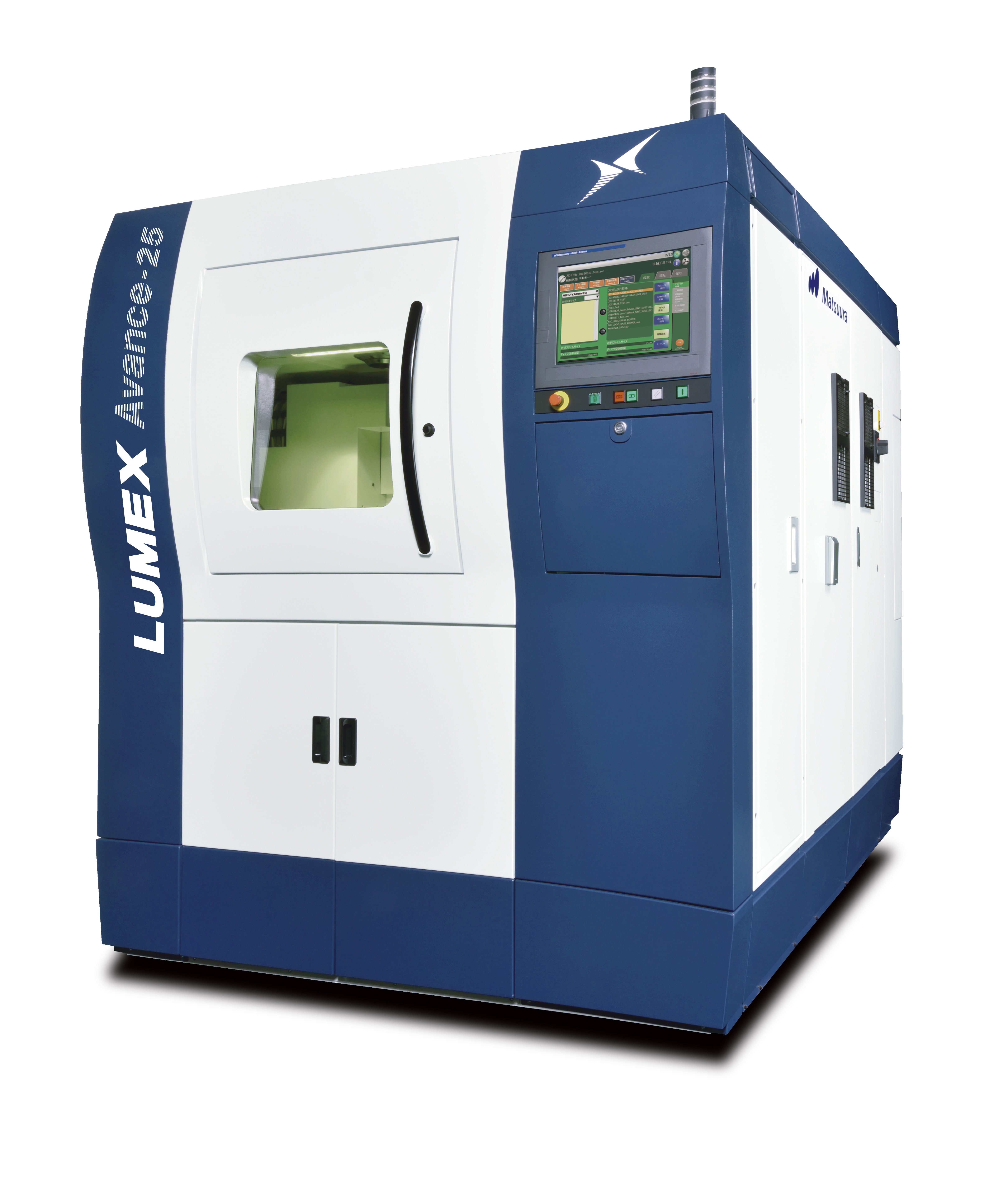

St. Paul, MN (June 20, 2018) — The Matsuura LUMEX is a hybrid metal 3D printer series which comprises metal laser sintering by fiber laser and high-speed milling of a machining center. Matsuura led the world in 2002 with the commercialization of a hybrid metal 3D printer and achieved a solid track record of Matsuura LUMEX Avance-25 mostly in the high value-added dies and molds market.

In the recent years the market demand for shorter sintering time (higher speed) has been growing. The new Matsuura LUMEX Avance-25 incorporates the company’s “know-how” of high-speed sintering, obtained through the development of the Matsuura LUMEX Avance-60 (maximum part size: 600 x 600 x 500 mm). Now available with a higher speed, the market applicable to hybrid 3D printers will expand, further increasing the appeal of the Matsuura LUMEX Avance-25.

To shorten the sintering time, the Matsuura LUMEX Avance-25 has a greatly enhanced powder distribution speed along with, optimized galvano control and sintering conditions, ensuring a sintering capacity of 14 cc/h* (double the existing). In addition, if equipped with a large-capacity 1-kW fiber laser system, the sintering capacity can be increased to 35 cc/h* (five times greater than existing). Likewise, the milling time can be reduced up to 75%* with a higher cutting feedrate and by supporting larger-diameter tools.

The Matsuura LUMEX Avance-25 can be installed with an optional full automatic powder supply, collection and reuse system. This system enables automatic metal powder supply and collection without operator contact with the powder, which ensures good workability and a clean working environment. In addition, U-axis stroke extension (185 mm extended to 300 mm) is available as an option. When the U-axis stroke is extended, large and heavy parts (256 x 256 x 300 mm / 150 kg) can be manufactured.

The capabilities of the CAM software dedicated to the Matsuura LUMEX series, LUMEX CAM, are also upgraded. By upgrading both machine and software at the same time, the machine has become easier for operators to use, which will contribute to the expansion of the metal 3D printer market.

Matsuura is planning to exhibit the LUMEX Avance-25 IMTS 2018: The International Manufacturing Technology Show in Booth 338148 in McCormick Place.

Features:

- High speed

- Material supply unit (squeegee blade) speed improvement

- Optimized galvano control and sintering conditions

- Expansion of sintering capacity per unit time – 14 cc/h* (double the existing, 400W)

- Powder suction function – Higher cutting feedrate and use of large-diameter tools: Milling time 75%* reduction

- New options

- Large-capacity 1 kW fiber laser – Sintering capacity per unit time: 35 cc/h* (2.5 times greater than standard, 400W)

- APR system (automatic powder recovery system) – Easy and safe material handling without operator contact

- U-axis stroke: 300 mm – Max. part size: 256 mm x 256 mm x 300 mm, allowable sintering weight: 150 kg

- New guard design, new operation panel

- LUMEX CAM update

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. delivers unmatched excellence in 5-axis, vertical, horizontal, linear motor, multi-tasking CNC machine tools and machines with a powder bed metal AM platform with machining capability. Matsuura Machinery USA, Inc. provides the service, applications and technical field support that have always been the Matsuura standard for business. For more information on Matsuura products, contact: Marketing@MatsuuraUSA.com or visit: www.matsuurausa.com.