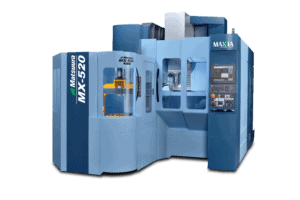

St. Paul, MN (July 12, 2017) Matsuura Machinery USA, Inc. announces the launch of the MX-520 PC4, a four-pallet automated version of the MX-520 single table 5-axis Vertical Machining Center model.

The MX-520 PC4 5-Axis Vertical Machining Center was designed in response to customer demand seeking a Matsuura automation solution for the MX-520 5-Axis Vertical Machining Center.

The MX-520 PC4 is equipped with 90 tools and an installed Universal Robot Interface to maximize the automation potential of this much anticipated addition to Matsuura’s 5-axis range.

With globalization and rapid advances in technology, today’s manufacturing environment is increasingly competitive. Along with manufacturers desire for cost reductions, the necessity for reliable, accurate and automated machining continues to grow.

Matsuura’s global customer base demands high speed, high accuracy and reliability with unrivaled technical, applications and service support. Matsuura’s dedication and commitment to the research and development of unique products incorporating the latest emerging technologies is the foundation of the company’s status as a technology leader.

“Offering ease of use and reliable 5-axis machining, the MX series delivers dynamic machining versatility, high accuracy, reliability and excellent cost efficient performance,” said a Matsuura Machinery USA, Inc. Spokesperson.

The Matsuura MX-520 maintains high rigidity, as well as, a generous machining envelope with excellent operability. The MX-520 also offers an assortment of configurations, which are ideal for all applications, all industries and all materials.

Matsuura’s MX-520 5-Axis Vertical Machining Center provides a simple, effortless and cost-effective transition for 3-Axis users making the transition to full 5-Axis operation. Designed with a RAM type structure, the MX-520 has a compact footprint with outstanding ergonomic design, allowing rapid set-up and processing of complex parts.

CAMplete TruePath software – an integrated suite of G-code editing, optimization, analysis, and verification tools is standard on every Matsuura MX-520.

“As a single table entry model into the high-quality world of Matsuura 5-axis machining, the MX-520 has been nothing short of a phenomenal success for Matsuura globally,” the Matsuura Machinery USA, Spokesperson continued.

The latest FANUC 31i (iHMI, 15-inch touch panel type) is installed and integrated with Matsuura’s renowned original software, which ensures ease of use, status at a glance and excellent operability.

The Matsuura MAXIA 12,000 RPM high-torque spindle is standard. A high-torque (187.0 Nm) motor is available to machine hard-to-cut materials. Matsuura’s 20,000 min-1 (108.7 Nm) spindle for high-speed machining of aluminum parts is available as an option.

The Matsuura MX-520 5-Axis Vertical Machining Center with the 4 pallet changer will debut September 18-23, 2017 at the Hannover Fairground in Germany. EMO Hannover is organized by the German Machine Tool Builders’ Association (VDW) on behalf of the European Association of the Machine Tool Industries (Cecimo). EMO Hannover is the leading trade fair of the sector, presenting an unequalled width and depth of products and services throughout all production areas, from the nucleus machine tool, to precision tools, to linking devices and industrial electronics.

Matsuura Machinery USA, Inc., located in St. Paul, MN is the U.S. subsidiary of Matsuura Machinery Corporation in Japan. Since 1935, Matsuura has delivered unmatched excellence in high speed and high precision CNC machine tools. From full 5-axis, vertical, horizontal, linear motor or multi-tasking CNC machine tools, Matsuura has been the forerunner in designing innovative technology and manufacturing solutions to a variety of industries around the globe. Matsuura Machinery USA, Inc. provides the service, applications, and technical field support that have always been the Matsuura standard for business.

For more information on Matsuura products, contact: [email protected]

www.matsuurausa.com