St. Paul, MN (June 26, 2014) — Matsuura Machinery USA announced today exhibition plans at the International Manufacturing Technology Show (IMTS) in Chicago’s McCormick Place to showcase automation solutions and new technologies that will increase production, minimize cost, increase quality and reduce set-up and lead times.

“Matsuura Machinery is well known as a pioneer in the development of high speed machining and the manufacture of automated, unmanned high accuracy CNC machine tools. We are enthusiastic to showcase at IMTS why Matsuura has been at the forefront of providing excellence through innovation since 1935,” said John Schwartz, Matsuura USA President.

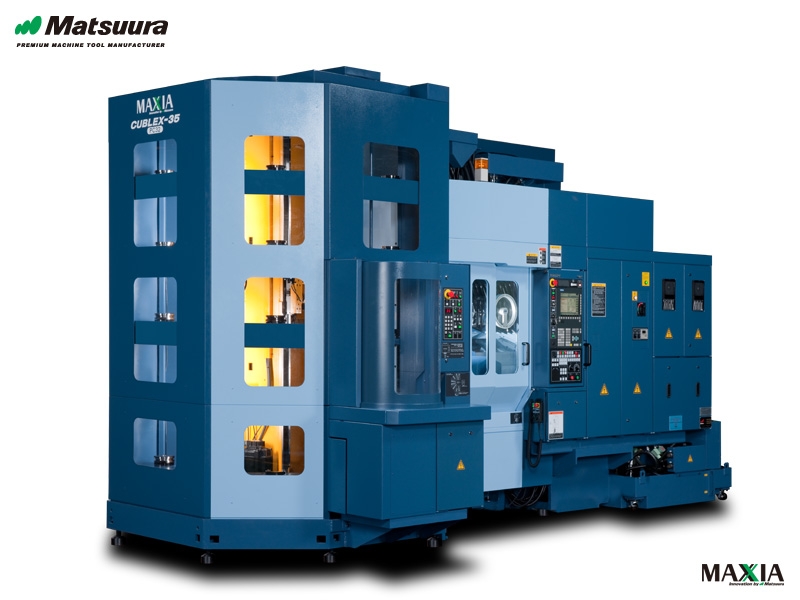

The company will feature five premium machining centers in the South Hall, Booth S-8640 Sept. 8-13, 2014. The planned exhibition includes: the CUBLEX-35 Five-Axis Multi-Tasking Machining Center, the H.Plus-300 Horizontal Machining Center, the LX-160 High-Grade Linear Motor Machine, the MAM72-100H Five-Axis Horizontal Machining Center, and the MX-850 Five-Axis Vertical Machining Center.

“Matsuura’s flexibility and automation capabilities, including our multi-pallet systems can simplify the production process and reduce cycle times tremendously,” said Schwartz.

“Matsuura’s unattended, lights-out machining is strategic in reducing labor costs and assisted many organizations to become much more competitive, allowing them to participate in additional markets,” Schwartz added.

At IMTS, Matsuura’s CUBLEX-35 Five-Axis Multi-Tasking Machining Center will feature precision milling, turning and grinding on the same platform. The B/C Axis Rotary Table, combined with Pallet Changer, enables high production milling and turning with exceptional precision. Matsuura’s CUBLEX-35 Five-Axis Multi-Tasking Machining Center will highlight a 20,000 RPM Milling Spindle, a 20,000 RPM Direct Drive C-Axis motor, a 320 Tool Matrix Magazine ATC, and Matsuura’s main spindle “chop-grinding” function.

Matsuura will also exhibit the H.Plus-300 Horizontal Machining Center with Automatic Tool Changer, 320 Tools and PC 15 Tower Pallet System. The H.Plus-300 is a rugged, high-speed precision horizontal machining center delivering long periods of reliable, unmanned operation, high accuracy, and exceptionally efficient production. Offering the ability to gain access to all sides of the part during production, the Matsuura H.PLUS-300 is capable of handling most modern materials that require high accuracy machining.

The Matsuura LX-160 High Grade Vertical Linear Motor Machine that will be presented at IMTS is the ultimate Five-Axis vertical machine equipped with linear motors for machining with high speed and high precision. The LX-160 is a dedicated and optimized Five-Axis design, not a Three-Axis machine with a “bolt on” 4th and 5th. The LX-160 is dedicated to the high-speed, high-accuracy market, with a focus on small work piece processing and linear motor drive technology. The LX-160 at IMTS will feature 42 pallets and 338 Tools.

Matsuura will also showcase the MAM72-100H Horizontal Machining Center, the largest Five-Axis model in the MAM72 Series. The Matsuura MAM72-100H

Five-Axis horizontal machining center allows cutting on all five sides in one operation and can achieve process integration and high-accuracy complex 5-Axis machining to meet the need for unmanned operation. This substantial machining center is one of very few to use linear motor, Five-Axis technology. The MatsuuraMAM72-100H Horizontal Machining Center will be exhibited with the high-torque, #50 Taper Spindle.

The final Matsuura machine to be exhibited at IMTS 2014 will be the MX-850Five-Axis Vertical Machining Center. The MX-850 Five-Axis Vertical Machining Center was developed in response to market demand for a large capacity, high quality and cost effective single table Matsuura 5-Axis machining platform. The MX-850 is compactly built, yet ensures high rigidity and a sufficient machining area and workability. The Matsuura MX-850 is compactly built, yet ensures high rigidity and a sufficient machining area and workability.

All Matsuura machine tools featured at IMTS will be equipped with CAMplete Truepath Software: an integrated suite of G-code editing, optimization, analysis and verification tools.

Matsuura Machinery USA, located in St. Paul, MN is the master importer of Matsuura machining centers in the United States. Matsuura delivers unmatched excellence in high speed and high precision CNC machine tools. The company’s unmanned, high accuracy machining equipment, including multi-pallet and multi-tasking machine tools provide manufacturing solutions to a variety of industries around the globe.

The company’s 40,000 sq. ft. facility includes a large showroom and demonstration area, conference and training rooms, machine storage areas, accessories and spare parts, as well as administrative, service, and engineering application support. A spindle repair facility is also currently being added.

Matsuura Machinery USA professionally markets and supports Matsuura equipment users through local distributors, making sure customers continue to have the high quality productivity solutions they require. From full five-axis, vertical, horizontal, linear motor or multi-tasking CNC machine tools, Matsuura has been the forerunner in designing innovative technology for the manufacturing industry.

For more information on Matsuura products, contact:

Matsuura Machinery USA, Inc.

325 Randolph Avenue

St. Paul, MN 55102

651-289-9700

www.www.matsuurausa.com